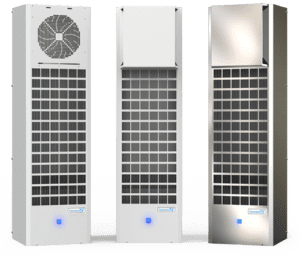

PWS Air/Water Heat Exchangers

For the Most Challenging Conditions

PWS Air/Water Heat Exchangers remove a considerable amount of heat while isolating sensitive electronics from a corrosive atmosphere outside of the enclosure.

PWS Air/Water Heat exchangers are widely deployed to protect variable frequency drives located in pump control panels, which are some of the most important pieces of equipment in manufacturing for various processing applications.

Paired with a Chiller, the PWS Air/Water Heat Exchanger provides a total cooling solution that manages process and/or controls enclosure heat gain and effectively removes it from the processing area.

Single source responsibility for the complete system ensures properly matched components that are engineered to work together – and to provide a custom fit to the most complex manufacturing plant’s processing equipment.

Ideal for manufacturing plants where:

- Hot, Dirty and Oily environments (Up to 110 °F)

- NEMA Type 12/3R/4/4x

- Heavy particulate, such as sand, soda ash, wood or paper dust, oil

- Conductive or static electricity

- Flammable, vibrations

- Energy conscious

Sample Applications:

- All manufacturing industries: Quality control

- Paper Converting: Gluing, sheeting, rewinding

- Metal: 3D metal printing, stamping, cutting, winders

- Rubber/Plastic: Extrusion, injection molding, blow molding

- Printing/Packaging: Labeling, printing

- Glass: Melting, pressing, sheeting

- Wood: Sawing, cutting, stacking, finishing, splitting, pressing , laminating

Click here to learn more: PWS Air/Water Heat Exchangers

Related articles:

Liquid Cooling Solutions for Plant Wide Machine Cooling.

Chillers for Industrial Automation and 3D Printing Applications.

DTS Cooling Units

For Harsh Environments

In harsh environments involving high temperatures, wash-down requirements, heavy particles or the presence of chemicals capable of damaging components (NEMA 4 or 12 environments), DTS Cooling Units are the perfect solution to seal out the ambient air, cool and re-circulate clean, cool air throughout the enclosure.

Offered in NEMA Type 4/4X 304 stainless steel, the DTS Cooling Unit utilizes an internal heater which eliminates the need for a drain line, and is coated with special polish to repel contaminants.

High temperature models can operate in ambient temperatures up to 140° F).

Pfannenberg DTS Cooling Units closed loop design isolates the external ambient air from the internally conditioned air eliminating the risk of contaminants entering the cabinet. The hermetically sealed compressor guarantees 100% cooling capacity efficiency. The absence of any refrigerant fill valves eliminates leak paths.

Ideal for manufacturing plants where:

- Hot and Clean or Hot and Dirty conditions (80° to 140 °F)

- NEMA Type 12/3R/4/4X

- Wash down requirements

- Component-damaging chemicals

- Particulate: sawdust, paper dust; pulp, rust

Ideal for these areas:

- All manufacturing industries: Packaging, shipping/receiving

- Paper Converting: Processing

- Metal: Cutting

- Rubber/Plastic: Melting, forming

- Printing/Packaging: Printing, labeling

- Wood: Assembly

- Glass: Grinding, sheeting

Click here to learn more: DTS Cooling Units

Related articles: Pfannenberg DTS Cooling Units to meet Wood Manufacturing Needs.

PKS Air/Air Heat Exchangers

For the Harshest Environments

One of the best technologies to use when there is a temperature difference between the internal target temperature and the surrounding temperature (∆T≥10°C) is air to air technology.

An air/air heat exchanger removes heat from inside of the enclosure to the cooler environment using the least amount of energy while still providing a closed loop ingress protection.

With five models to choose from, our closed loop PKS Air/Air Heat Exchangers will protect all electronics that don’t require a remote cooling source, and take advantage of our next generation Kinetic Cooling System™ to exchange and remove heat from an electrical enclosures.

Industrial automation is used in almost every area of a manufacturing plant, and most electronics utilize a high number of VFDs (variable frequency drives), an extremely expensive and critical piece of machinery. Technology advancements in VFD drives, which are rated to a min. of 103°F; allow the required ∆T needed for a PKS Air/Air Heat Exchanger to be effective.

Ideal for manufacturing plants where:

- Cool, dirty conditions (-13° to 131°F)

- NEMA Type 12/3R/4/4X

- Temperature controlled environment

- Need to reduce heat condensation

- Protection against corrosion and contamination

- Energy conscious

Sample Applications:

- Packaging

- Shipping/receiving

- Quality control

- Assembly

Click here to learn more: PKS Air/Air Heat Exchangers

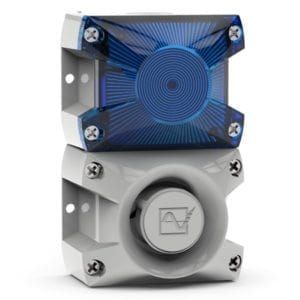

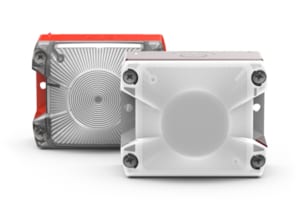

Stack Lights, Signaling and Alarms

For Areas where Employee and Public Safety is Critical

In many plants, there is a clear lack of signaling and alarms leading to potential safety issues. In others, signaling confusion occurs when manufacturing plants use the same signaling for different issues.

To provide a safe environment in all areas of your plant, we offer an award-winning range of solutions to ensure adequate signaling and alarm coverage and avoid signaling confusion. And where hazardous vapors can occur, for example we provide ruggedized alarms that operate with any gas detection system.

Metal and other plants with welding, cutting, and machining equipment, use our NEMA type 4/4X and IP 66 rated PATROL & PYRA® Visual and Audible Signaling Devices as they are designed for extreme temperatures and withstand exposure to dust, liquids, water spray, and corrosives.

Our QUADRO Explosion Proof LED Lights are perfect for hazardous environments as they offer flexible, ultra-bright color changing or single color LEDs with selectable signaling modes and colors. When signaling is needed in extremely hot areas, we offer Patrol and PYRA devices for use in -40ºF to +131ºF environments.

With robust flashing sounders offering more than eighty tones, our signaling solutions provide widespread coverage through each alarm, significantly reducing the number of signaling devices needed, resulting in an application that not only ensures industrial safety, but is economical as well.

Ideal for manufacturing plants where:

- Machine alarming, indication, or warning required

- Gas detection for carbon black, diesel fuel or odor-reducing, and chemical leaks

- Ruggedized, robustness due to humidity

- Flammable materials present

Sample Applications:

- All manufacturing industries: Packaging, shipping/receiving, quality control

- Metal: Welding, cutting, machining, 3D printing

- Rubber/Plastics: Conveyor systems

- Printing/Packaging: Flammable compounds

- Wood: CNC usage, finishing with flammable materials

- Material Handling: Conveyor Systems, Palletizers

- Glass: Blow molding

Click here to learn more: Signaling Solutions

Related articles: NEW PYRA® LED Alarms: Flexible Enough for Use in Any Signaling Application

Filterfans®

Trust in the Original

Our patented Filterfans® are an ideal cooling solution in areas manufacturing plants where the ambient air is always lower than the temperature required in the electrical enclosure, as they assist the natural convection of the air and help to avoid hot spots. The optional Rainhood’s metal shell provides additional protection from the environment, especially areas exposed to heavy spray.

Pfannenberg’s Filterfan® + Rainhood combination is the market-leading solution for use in extreme environments. The Rainhood’s metal shell provides solid protection against breaking, hides the filter fan from vandalism, provides another barrier against the entrance of water in washdown procedures.

Ideal for manufacturing plants where:

- Cool, clean conditions (-40° to 131°F)

- NEMA Type 12

- Areas exposed to outdoors or heavy spray

Ideal for these areas:

- All manufacturing industries: Packaging, shipping/receiving, quality control