DTS 3661C

SIDE MOUNT COOLING UNITS

13709-25930 Btu/h

Our DTS 3661C (NEMA Type 3R/4) new improved version of our former DTS 3661 indoor cooling units, have the highest Cooling Capasity Per Density (CCPD) available on the market. Housing: galvanized sheet steel. These units are ideal for high heat loads, especially high horsepower drive enclosures. Cover: electrostatically powder coated RAL 7035 (light grey) or ANSI 61 grey.

Product Overview:

- Highest cooling capacity in the smallest footprint possible

- Easy Wiring: Hinged Panel access

- No more phasing (460v)

- Robust and Service Friendly : HP & LP switch to protect the compressor /Easy access to components

- Highly visible Fault indicator on the front of the unit

Replacing an older DTS 3661 model with this newer DTS 3661C model?

If purchasing this unit as a replacement for our older DTS 3661 you will need to also purchase an adapter plate. We have 2 adapter plates available for this unit depending on the color (18380000033 RAL 7035 Light Grey Old to New adapter or 18380000034 ANSI 61 Dark Grey Old to New Adapter).

Please note if purchasing for a new installation then no adapter plate is required.

Features

Closed Loop Design

Designed to isolate the external ambient air from the internally conditioned air eliminating the risk of contaminants entering the cabinet.

Service Friendly Electric Panel

Flip down hinged design to allow easy asses to electrical controls. Plug-n-play power connection for easy wiring (Female connector provided).

Hermetically Sealed Reciprocating Compressor

The absence of any refrigerant fill valves eliminates leak paths. Recharging is never needed. Reciprocating Compressor eliminate phase mis-wiring.

Active Condensate Management

Condensation is a natural byproduct of refrigeration. The heated condensate collection pan boils this off thereby eliminating the need for drain tubes and buckets. To conserve power, this heater only activates when necessary.

High Airflow Backward Curve Impeller Fan

Provides high airflow preventing hotspot especially in populated or multiple bay enclosures. Best in Class fan providing long service life.

Rugged Design for All Environment

Powder coated or stainless-steel cover designed for harsh manufacturing environments. Additional rainhood cover for DTS 3461C Outdoor (Type 3R/4) and DTS 3461C Washdown (Type 4/4X) designs.

Efficient and Extended Life Design

Zinc coated micro-channel design provides up to 40% increased in heat rejection boosting the overall cooling performance. The coating provides additional protection towards corrosive environment prolonging the service life.

Pressure and Thermal Overload Protection

High pressure cutout and thermal switches ensures safety by shutting off the compressor and fans in unforeseen event of excessive pressure or heat to protect unit from costly repair

Highly Visible Status Light

Provides easy visual indication on the running status of the cooling unit. Alerting maintenance team of any error when happened.

Technical Data Overview

| DTS 3661C | 230 V | 400/460 V |

|---|---|---|

| PART NUMBER | 13384039355 | 13384036355 |

| FREQUENCY (Hz) | 60 | 50/60 |

| POWER CONSUMPTION (W) | 3678 | 3060 |

| NOMINAL (RUN) CURRENT* (@35A/35A) | 16.06 | 5.18 |

| FUSE (max.)** CLASS CC | 30 | 10 |

| NOISE LEVEL*** dB(A) | 81 | |

| WEIGHT lb (kg)(without packaging) | 234.8 (106.5) | |

| DIMENSIONS in | 57.2 x 15.8 x 16.1 | |

| *For the MCA (Maximum Current Ampacity) value per UL, please consult product technical datasheets available above. **Suitable for Transformer Inrush Protection ***(According to EN ISO 3741) |

||

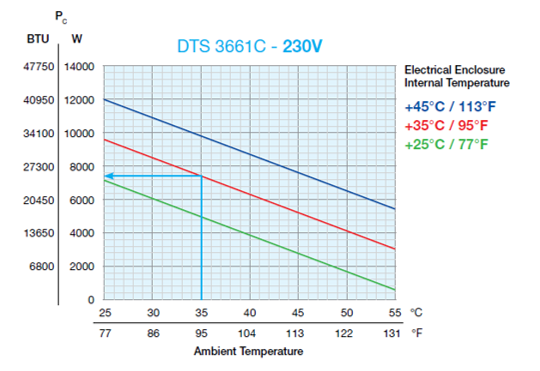

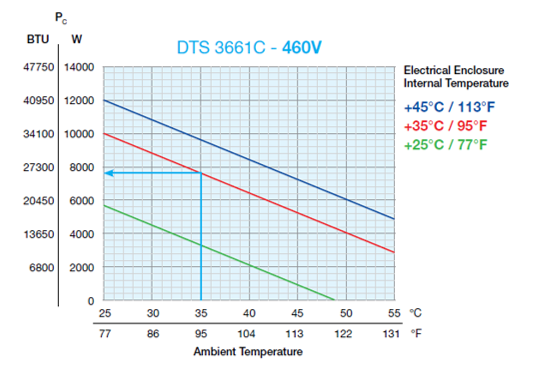

Performance Curve

Additional Data

| AMBIENT TEMPERATURE RANGE | + 25°F … + 131°F / + 4°C… + 55°C | |

| CONTROL RANGE (adjustable) | SC | + 77°F … + 113°F / + 25°C … + 45°C; factory setting + 95°F / + 35°C |

| REFRIGERANT | type | R134a |

| quantity | 450g | |

| CONDENSATE MANAGEMENT | Integrated condensate management system with condensate drain | |

| PROTECTION SYSTEM ACCORDING TO NEMA TYPE | NEMA Type 3R/4(against enclosure when properly installed) | |

| NEMA 1 towards the surroundings when properly installed | ||

Subject to technical amendments and misprints.

Latest Posts

Unlocking Energy-Efficient Cooling with the DHS Hybrid SeriesApril 11, 2025 - 2:02 PM

Unlocking Energy-Efficient Cooling with the DHS Hybrid SeriesApril 11, 2025 - 2:02 PM Pfannenberg USA Introduces Outdoor 3R PTF 1200 High CFM Top-Mounted FilterfanFebruary 18, 2025 - 8:39 AM

Pfannenberg USA Introduces Outdoor 3R PTF 1200 High CFM Top-Mounted FilterfanFebruary 18, 2025 - 8:39 AM Pfannenberg Highlights Range of Thermostat ProductsJanuary 23, 2025 - 3:09 PM

Pfannenberg Highlights Range of Thermostat ProductsJanuary 23, 2025 - 3:09 PM Enhancing Port Safety with Pfannenberg’s PA X 5-05 Signaling SolutionDecember 4, 2024 - 11:48 AM

Enhancing Port Safety with Pfannenberg’s PA X 5-05 Signaling SolutionDecember 4, 2024 - 11:48 AM