DTS 3281

SIDE MOUNT COOLING UNITS

7000-8500 Btu/h

Our DTS 3281 (NEMA Type 4/4x) stainless steel cooling units are an ideal solution for a wide variety of wash-down applications. These units utilize a long internal air path to capture heat above the components and provide cool air below. Housing: stainless steel 304. Cover: stainless steel 304

Features

ERP Efficiency Certified

As a component of the Kyoto Protocol to reduce carbon monoxide emissions, the European Energy Related Products (ERP) Directive includes an efficiency rating for fans. Pfannenberg proudly utilizes components which adhere to these requirements.

High Airflow Backward Curve Impeller Fan

Provides high airflow in a long lasting, single bearing design. Outperforms typical two-bearing blowers with nearly twice the lifespan.

Closed Loop Design

Designed to isolate the external ambient air from the internally conditioned air eliminating the risk of contaminants entering the cabinet.

Thermal Overload Protection

Compressor and fan motors are outfitted with integral temperature switches to shut down the unit in the event of excessive temperature. This increases the operating life of the compressor by preventing thermal overload trips.

Pressure Overload Protection

High pressure cutout switch ensures safety by shutting off the compressor in the event of excessive pressure appearing in the refrigeration circuit.

Environmentally Friendly

Utilizes HFC-free R134a refrigerant versus a blended refrigerant for easier service and minimized negative impact to the environment.

Maintenance Free, Filterless Design

The wide fin spacing is less susceptible to clogging from dirt buildup which can cause the unit to work harder and hamper efficiency.

Active Condensate Management

Condensation is a natural by-product of refrigeration. The heated condensate collection pan boils this off thereby eliminating the need for drain tubes and buckets.To conserve power, this heater only activates when necessary.

Hermetically Sealed Compressor

The absence of any refrigerant fill valves eliminates leak paths. Recharging is never needed. 100% cooling capacity efficiency is ensured.

Corrosion Protection

Outdoor and wash-down units have a special coating on pipes and coils on the ambient side of the unit to provide maximum protection from saltwater, sour gas, and other corrosive substances.

Thermal Expansion Valve

Regulates the flow of refrigerant based on thermal demand for efficient performance over the entire operating temperature range.

High Ambient Performance

The DTS 3000 Series Cooling Units were designed utilizing high temperature compressors and larger condensers. Both the indoor NEMA Type 12 units and outdoor units perform very well in environments that require cooling where the maximum ambient temperature is 131° F.

Quiet Operation

Achieved with waste heat exhausted through the bottom.

Rugged Design

Powder coated steel or stainless steel cover designed for manufacturing environments. Easily painted to match enclosure or machine.

Technical Data Overview

| DTS 3281 | 115 V | 230 V | 400/460 V |

|---|---|---|---|

| PART NUMBER | 13385744158 | 13385741158 | 13385736158 |

| FREQUENCY (Hz) | 60 | 50/60 | 50/60 |

| POWER CONSUMPTION (W) | 1680 | 1425 | 1400 |

| NOMINAL (RUN) CURRENT* (@35A/35A) | 11.6 | 5.6 | 2.6 |

| FUSE (max.)** CLASS CC | 30 | 10 | 6A |

| NOISE LEVEL*** dB(A) | <73 | <73 | <73 |

| WEIGHT lb (kg)(without packaging) | 132 (60) | 132 (60) | 148 (67) |

| DIMENSIONS | 47.6 in. (1209 mm) h x 15.6 in. (395 mm) w x 10.6 in. (269 mm) d | ||

| *For the MCA (Maximum Current Ampacity) value per UL, please consult product technical datasheets available above. *** (According to EN ISO 3741) |

|||

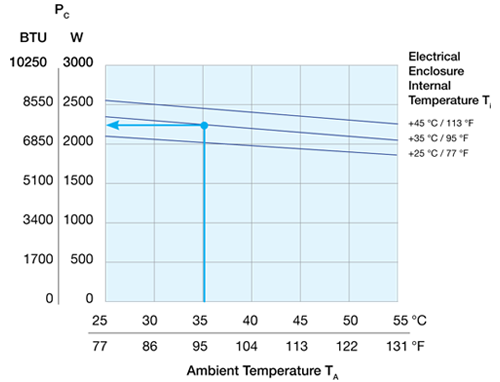

Performance Curve

Additional Data

| AMBIENT TEMPERATURE RANGE | + 32°F … + 131°F / + 0°C … + 55°C | |

| CONTROL RANGE (adjustable) | SC | + 77°F … + 113°F / + 25°C … + 45°C; factory setting + 95°F / + 35°C |

| REFRIGERANT | type | R134a |

| quantity | 700g | |

| CONDENSATE MANAGEMENT | active condensate evaporation system with safety overflow | |

| PROTECTION SYSTEM ACCORDING TO NEMA TYPE | NEMA Type 4/4x(against enclosure when properly installed) | |

| NEMA 1 towards the surroundings when properly installed | ||

Subject to technical amendments and misprints.

Latest Posts

Unlocking Energy-Efficient Cooling with the DHS Hybrid SeriesApril 11, 2025 - 2:02 PM

Unlocking Energy-Efficient Cooling with the DHS Hybrid SeriesApril 11, 2025 - 2:02 PM Pfannenberg USA Introduces Outdoor 3R PTF 1200 High CFM Top-Mounted FilterfanFebruary 18, 2025 - 8:39 AM

Pfannenberg USA Introduces Outdoor 3R PTF 1200 High CFM Top-Mounted FilterfanFebruary 18, 2025 - 8:39 AM Pfannenberg Highlights Range of Thermostat ProductsJanuary 23, 2025 - 3:09 PM

Pfannenberg Highlights Range of Thermostat ProductsJanuary 23, 2025 - 3:09 PM Enhancing Port Safety with Pfannenberg’s PA X 5-05 Signaling SolutionDecember 4, 2024 - 11:48 AM

Enhancing Port Safety with Pfannenberg’s PA X 5-05 Signaling SolutionDecember 4, 2024 - 11:48 AM