PWW 6000

WATER/WATER HEAT EXCHANGERS

6 kW – 20,500 Btu/h

Our PWW 6000 Water/Water Heat Exchangers is based on the passive cooling principle. This product is ideal for utilizing a contaminated water source, such as river water or low quality tower water without compromising the critical liquid cooled components. Two separate circuits allow the heat to be transferred from the “dirty” side to the clean side protecting electronic components such as liquid cool drives. Design: Rugged construction – (G90) galvanized steel with polyester powder coat finish

Features

Passive Cooling System

Due to the smart design of the closed loop circuit PWW units can be easily adapted to the existing water supply.

Expansion Vessel

A properly sized thermal expansion tank will accommodate the additional volume of water created through expansion during the heating cycle.

3-way valve for primary water regulation

Means the highest reliability, complete accuracy, wide temperature control range and programmable set-point.

Plate Heat Exchanger

Made of stainless steel to prevent corrosion and grant high performance.

Centrifugal Pump

Multi stage pump for high flow rates even at high pressure resistance.

Digital Controller

With clear error message an easily editable set point.

Service Friendly Design

Easy removable panels allow quick access to internal components and reduced service cost.

Technical Data Overview

| PWW 6000 | 230 V | |

|---|---|---|

| PART NUMBER | 42120405005 | |

| COOLING CAPACITY* (WP15/WS25) | Btu/h | 20500 |

| kW | 6 | |

| PRIMARY WATER INLET (°C | F) | +5 … +30 | +41 ... +86 | |

| SECONDARY WATER OUTLET (°C | F) | +10 … +35 | +50 ... +95; factory setting +20 | +68 | |

| MAX POWER CONSUMPTION (W) | 3000 | |

| MAX CURRENT CONSUMPTION (A) | 5.35 | |

| COOLANT CONNECTIONS (bsp) | 1" | |

| MAX NOISE LEVEL (@ 60 Hz) | 64 dB (A) | |

| WIDTH in (mm) | 23 | |

| DEPTH in (mm) | 32 | |

| HEIGHT in (mm) | 20 | |

| DRY WEIGHT lb (kg) | 110 | |

| *@ 10°F difference between entering supply water & leaving process water at 1:1 flow rate | ||

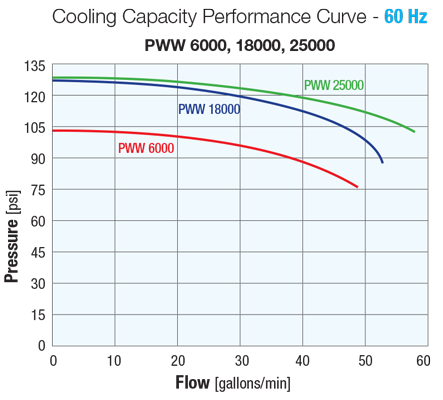

Performance Curve

Subject to technical amendments and misprints.

Latest Posts

Unlocking Energy-Efficient Cooling with the DHS Hybrid SeriesApril 11, 2025 - 2:02 PM

Unlocking Energy-Efficient Cooling with the DHS Hybrid SeriesApril 11, 2025 - 2:02 PM Pfannenberg USA Introduces Outdoor 3R PTF 1200 High CFM Top-Mounted FilterfanFebruary 18, 2025 - 8:39 AM

Pfannenberg USA Introduces Outdoor 3R PTF 1200 High CFM Top-Mounted FilterfanFebruary 18, 2025 - 8:39 AM Pfannenberg Highlights Range of Thermostat ProductsJanuary 23, 2025 - 3:09 PM

Pfannenberg Highlights Range of Thermostat ProductsJanuary 23, 2025 - 3:09 PM Enhancing Port Safety with Pfannenberg’s PA X 5-05 Signaling SolutionDecember 4, 2024 - 11:48 AM

Enhancing Port Safety with Pfannenberg’s PA X 5-05 Signaling SolutionDecember 4, 2024 - 11:48 AM