CC 6101

CHILLERS

1200-6800 W / 4056-23100 Btu/h / 0.3-1.9 TONS

Our CC 6101 (NEMA Type 1) compact and efficient chillers offer many features found only in larger models. These smaller frame chillers are the solution for integrated motor and/or process cooling required for high-speed machining centers. Single phase power requirements make them easily installed in most commercial and industrial settings.Design: Rugged construction – (G90) galvanized steel with polyester powder coat finish

Features

High Airflow for Efficient Operation

Axial fans deliver high volume airflow across the condenser for effective dissipation of waste heat while fan cycling provides maximum refrigeration efficiency and energy conservation.

Designed to Handle Tough Environments

Large, finned-tube condensers provide a high level of energy efficiency and fouling resistance.

Larger Surface Area Brazed-plate Evaporators for Lower Energy Usage

With large heat transfer surfaces in a compact size, brazed-plate evaporators offer efficient operation for both heat transfer and coolant flow, resulting in reduced pumping energy. For optimum performance, externally equalized thermal expansion valves are utilized to continuously manage refrigerant flow based on load.

Long Service Life & Wider Range of Performance

Centrifugal coolant pumps offer a wide range of flow and pressure capabilities to fulfill a variety of pipe-run requirements. Non ferrous construction eliminates corrosion and problems surrounding coolant contamination.

Large Coolant Capacity to Absorb Rapid Changes in Heat Load

Vented polypropylene reservoir tanks effectively accommodate rapid changes in heat load thereby permitting the system to cycle efficiently.

High Efficiency, Long Life Compressors

Heavy-duty reciprocating compressors provide high efficiency and long service life.

Durable, Weatherproof Construction

Galvanized steel frame and panels are polyester powder coated in light grey (RAL 7035) to resist corrosion.

Continuous Display Info & Remote Operation

The feature-rich, plug in controller with digital display provides ease of setup and monitoring of all operating conditions including warning and alarm indications. Remote start/stop capability and general alarm contacts are provided. An optional wired remote control pad with 400 ft. range is available.

Protected Electronics and Controls Support Safe & Efficient Operation

Electrical controls for safe and efficient operation include high, low and fan control refrigerant pressure switches, coolant flow and freeze protection. All sensitive devices are contained within a NEMA 1 rated enclosure and built to UL508a standards.

Flexible Mounting

Channel bases are included to facilitate lift truck handling and permanent foundation mounting. Optional casters are available.

Technical Data Overview

| CC 6101 | 115 V | 230 V | |

|---|---|---|---|

| PART NUMBER | 42630115112 | 42630115212 | |

| CAPACITY* | Btu/h | 4056 | 4056 |

| kW | 1.2 | 1.2 | |

| Tons | 0.34 | 0.34 | |

| NOMINAL CURRENT (A) | 18 | 9 | |

| TANK VOLUME (gal) | 2.7 | 2.7 | |

| COOLANT CONNECTIONS (NPT-F) | 1/2 | 1/2 | |

| WIDTH in (mm) | 24 (610) | 24 (610) | |

| DEPTH in (mm) | 19 (483) | 19 (483) | |

| HEIGHT in (mm) | 28 (711) | 28 (711) | |

| DRY WEIGHT lb (kg) | 200 (91) | 200 (91) | |

| *Water @ 64°F CWS / 90°F Ambient / 60Hz | |||

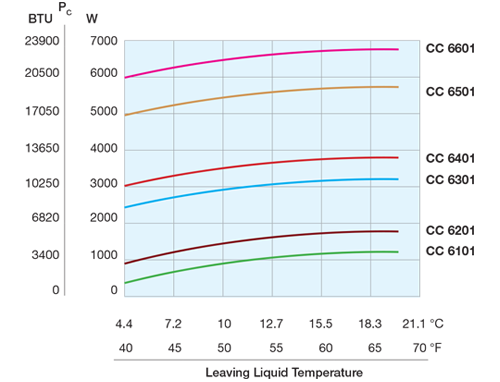

Performance Curve

Cooling Capacity

Subject to technical amendments and misprints.

Latest Posts

Unlocking Energy-Efficient Cooling with the DHS Hybrid SeriesApril 11, 2025 - 2:02 PM

Unlocking Energy-Efficient Cooling with the DHS Hybrid SeriesApril 11, 2025 - 2:02 PM Pfannenberg USA Introduces Outdoor 3R PTF 1200 High CFM Top-Mounted FilterfanFebruary 18, 2025 - 8:39 AM

Pfannenberg USA Introduces Outdoor 3R PTF 1200 High CFM Top-Mounted FilterfanFebruary 18, 2025 - 8:39 AM Pfannenberg Highlights Range of Thermostat ProductsJanuary 23, 2025 - 3:09 PM

Pfannenberg Highlights Range of Thermostat ProductsJanuary 23, 2025 - 3:09 PM Enhancing Port Safety with Pfannenberg’s PA X 5-05 Signaling SolutionDecember 4, 2024 - 11:48 AM

Enhancing Port Safety with Pfannenberg’s PA X 5-05 Signaling SolutionDecember 4, 2024 - 11:48 AM