Large Packaged Chillers

Pfannenberg Liquid Solutions – Now That’s Cool™

Pfannenberg’s chillers guarantee a central and cost-effective solution and perfectly answer industry’s need for precise temperature control and absolute reliability, 24 hours a day, 365 days a year. Design is compact, maintenance friendly and they easily match global requirements due to the flexibility in terms of certifications.

Pfannenberg Packaged Chillers specifications:

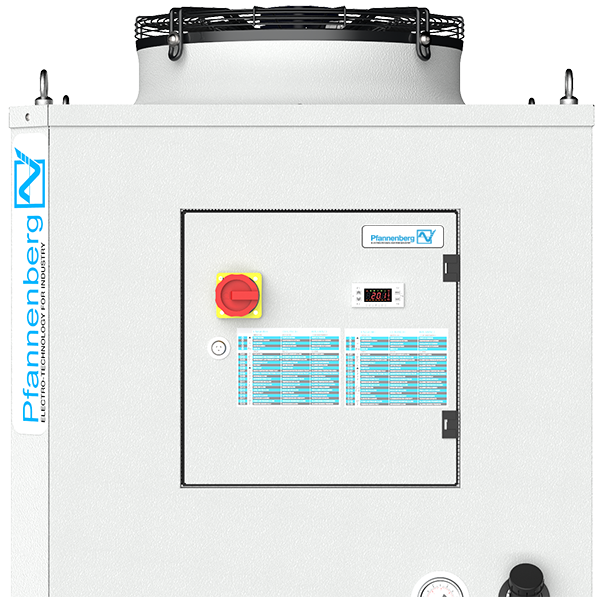

Large Packaged Chiller allows the maximum cooling capacity in the smallest possible footprint. Ready to use, Pfannenberg chillers require only piping & power to install a solution for process cooling applications – we’ll even provide the coolant.

- Each chiller model includes the pump, tank, refrigeration system and controls required for simple installation and reliable, efficient operation.

- Model sizes ranging up to 30 Tons insure that the proper capacity is available for most applications.

- Ethylene & propylene glycol coolants with proper corrosion inhibitors are available in a variety of packaging options – both full strength and pre-mixed.

- Equipment options are available to easily customize standard chillers to meet specific application requirements.

- These chillers are a perfect match for Pfannenberg Series PWS Air/Water Heat Exchangers when a local source of cooling is not available.

Why Choose Pfannenberg Large Packaged Chillers?

Energy Efficient

Energy Efficient

Heavy-duty reciprocating compressors provide high efficiency and long service life. Crankcase heaters are included with all models.

High Cooling Capacity

High Cooling Capacity

Axial fans deliver high volume airflow across the condenser for effective dissipation of waste heat while fan cycling provides maximum refrigeration efficiency and energy conservation.

Service Friendliness

Service Friendliness

Minimum MTTR (Mean Time To Repair) and the shortest time needed to replace units thanks to service-friendly accessibility, standardized parts and a carefully thought out plug-and-play concept minimizing your repair costs and downtime.

Adapted to Any Environment

Adapted to Any Environment

Large, finned-tube condensers provide a high level of energy efficiency and fouling resistance. Can be installed either inside or outside.

Large Packaged Chillers Models

Specifically developed to meet the demanding requirements of today’s industrial applications, the EB chiller allows the maximum cooling capacity in the smallest possible footprint. With a long list of standard features and many available options, Pfannenberg’s EB 2.0 Series provides the best choice for recirculated cooling of machinery, hydraulics, automation components, etc.

Standard Features:

- Non-ferrous hydraulic circuit

- Wired remote control on/off ready

- Hot gas by-pass refrigerant circuit

- Micro-channel condenser

- Programmable smart controller

- Internal hydraulic bypass circuit

- Electrical tank level switch

- Coolant flow switch