Product Development

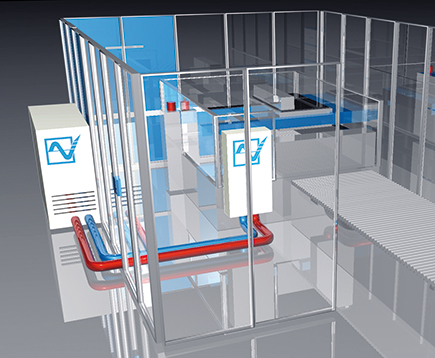

Pfannenberg’s research & development facility offers the perfect venue for evaluating your products within the thermal management, air conditioning and/or signalling technologies realm. We can provide the resources needed to turn your basic product ideas into well-developed, revenue-generating products in less time, and for less cost, than you might expect.

Lower your fixed costs by letting our professional team of experienced engineers handle your R&D so you can focus on the “big picture.”

- Conception

- Development of specifications and test plans (design)

- Design

- Flow simulation (CFD)

- Prototype construction

- Prototype validation

- Document management

Product Design and Validation

The cost of maintaining a testing laboratory for product validation is prohibitive for many companies. Pfannenberg is pleased to offer our well-staffed, state-of-the-art testing facilities as an economical alternative to in-house validation.

An extensive range of testing services is available to provide a detailed evaluation of your product:

- Environmental simulations in the climatic chamber

- Infrared measurements

- Protection class tests (IP protection)

- Transport and vibration tests

- Air quantity and light intensity measurements

- EMC tests / noise emission tests

- Air flow simulation (CFD)

- We work with you to develop a goal-specific testing plan;we organize and perform all necessary tests, and deliver a comprehensive report

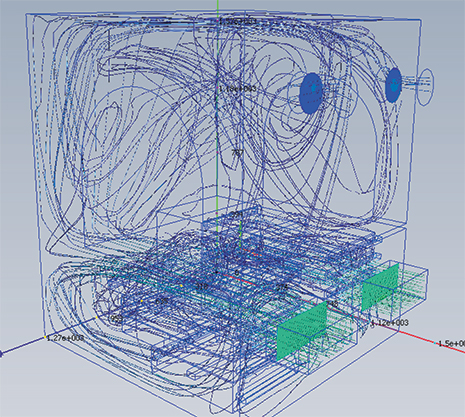

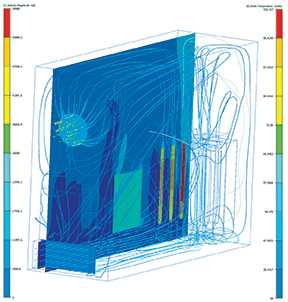

Computational Fluid Dynamics Analysis

By addressing complex flow and thermal challenges up front in the design process, a complete performance picture is captured – allowing our customers to get their products to market faster, deliver more innovative, efficient and profitable solutions, and reduce overhead and offering price as well as reduce warranty exposure. Fast, affordable, cost-effective project support for companies who have the need for CFD analysis, but not the budget. Airflow analysis is just as critical as capacity sizing.

Benefit of CFD Analysis:

- Get yout products to market faster.

- Deliver more innovative, efficient and profitable solutions.

- Reduce overhead and offering price.

- Reduce warranty exposure.

- Fast, affordable, cost-effective project support for companies.

Using CFD Analysis for OEM Product Configuration

Pfannenberg used CFD Analysis to help an OEM customer determine the most efficient method for component configuration within their electrical control panel. Our engineering team analyzed each electrical component, how it was influenced by the air around it and the amount of heat generated. The customer was able to reconfigure the placement of the electrical components to support better airflow and also design in placement of additional panel fans to improve the recirculation of air forming in the lower portion of their cabinet.

Simulating temperature and airflow characteristics before finalizing product configuration allowed our customer to reduce possible recalls and repairs due to equipment failure.