Money-saving approach yields longer service life while conserving energy.

Control Panel Cooling Technique Helps Mitigate Hydrogen Sulfide Corrosion Problems with Wastewater Pumping Systems

Air To Water Heat Exchangers provide an energy efficient and reduced manintenance method for cooling electrical control panels.

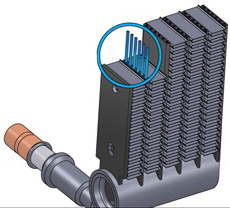

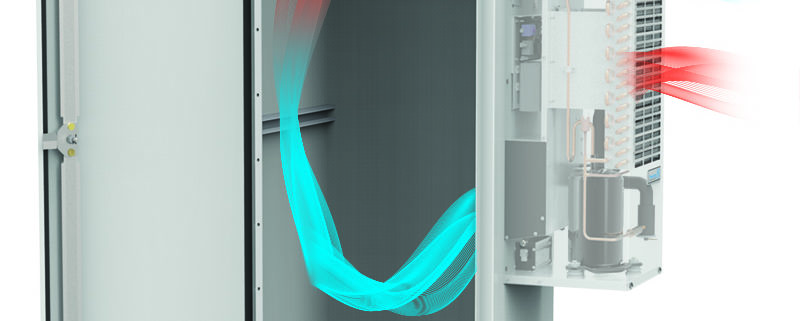

Enclosure Cooling Units offer a straightforward active-cooling technique for pump control panels, however, they are not necessarily the best choice for all installation locations. Dirt, dust, and other airborne contaminants can clog condenser coils; while corrosive gasses in the environment can lead to premature failures.On the other hand, Air To Water Heat Exchangers can satisfy the same requirements without circulating ambient air within the housing, thereby eliminating the clogging and corrosion problems associated with airborne contamination.

A common threat to organic wastewater handling and treatment systems is the presence of hydrogen sulfide gas. Not only is this gas toxic to humans, but it also contributes heavily to corrosion problems in pipes, structures, instrumentation, and electrical systems. Lift stations and pumping systems are particularly vulnerable as H2S sour gas readily attacks copper used in wires, electrical contacts, and cooling units used on motor control centers (MCC’s).

Electronics cooling is vital for MCC’s containing the variable frequency drives (VFD’s) that are used to maintain efficient operation by conserving energy through regulating the speed at which pumps operate. Since VFD’s generate a considerable amount of heat, it is necessary to employ an active enclosure cooling technique in order to keep VFD’s operating within acceptable temperature limits. The absence of effective cooling will quickly allow VFD’s to overheat, shut down, or even catastrophically fail. In addition to being an economic loss, such outages disrupt production and affect the efficiency of plant operations.

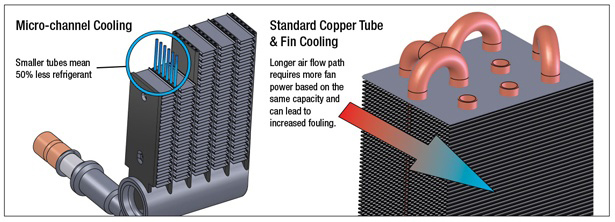

Effective electrical enclosure cooling for environments where H2S gas is present must utilize a closed loop technique to ensure that sour gas is not introduced into the enclosure where it could harm wiring, electrical connections, switches, and other components. In fact, for many installations it is advantageous to deploy an air or nitrogen purge system which creates a positive pressure within the enclosure in order to keep undesirable ambient elements, including sour gas, outside of it. As opposed to an open loop system that uses fans to draw ambient air into and push heat out of the enclosure, a closed loop system maintains isolation of the ambient air and permits the NEMA rating of the electrical enclosure to be maintained. Examples of closed loop cooling equipment for electrical enclosures include cooling units (also known as enclosure air conditioners or enclosure AC) and Air To Water Heat Exchangers.

Effective electrical enclosure cooling for environments where H2S gas is present must utilize a closed loop technique to ensure that sour gas is not introduced into the enclosure where it could harm wiring, electrical connections, switches, and other components. In fact, for many installations it is advantageous to deploy an air or nitrogen purge system which creates a positive pressure within the enclosure in order to keep undesirable ambient elements, including sour gas, outside of it. As opposed to an open loop system that uses fans to draw ambient air into and push heat out of the enclosure, a closed loop system maintains isolation of the ambient air and permits the NEMA rating of the electrical enclosure to be maintained. Examples of closed loop cooling equipment for electrical enclosures include cooling units (also known as enclosure air conditioners or enclosure AC) and Air To Water Heat Exchangers.

Cooling units offer the advantage of a being a plug and play solution – they simply hang onto the outside of the enclosure and are connected to power already available inside the enclosure. However, these compressor-based refrigeration systems consume a fair amount of energy and require periodic maintenance. Additionally, to endure the sour gas environment, exposed copper pipes and condenser coils must be treated with a conformal coating – which is not necessarily standard. Over time, the need to clean condenser coils – which may require partial disassembly of the cabinet – can lead to scratched paint, compromised coatings, and eventual corrosion.

Air To Water Heat Exchangers offer several advantages making them the preferred method for closed-loop, electrical enclosure cooling. Acquisition and operating expenses are significantly lower than those of a compressor-based cooling unit.

Additionally, this product is virtually maintenance free and since there is no ambient air circulation within the unit, there is no risk of H2S sour gas corrosion to internal components.

There are, however, two challenges with acquiring and implementing these units:

- The units must be specified as the solution of choice with the MCC or pump system integrator.

- The units must be connected to a viable source of clean water or coolant to circulate through the heat exchanger coil.

Another viable implementation is to consider retrofitting cooling units with air-to-water heat exchangers. This modification can be readily accomplished without difficulty since some units share the same enclosure cut-out. For dissimilar cutouts, an adaptor plate may be required to reduce the size of the opening.

Click here to download the Case study in PDF

Need more information on Pfannenberg’s PWS Air to Water Heat Exchangers? Click here and discover all the advantages of this product!

Effective electrical enclosure cooling for environments where H2S gas is present must utilize a closed loop technique to ensure that sour gas is not introduced into the enclosure where it could harm wiring, electrical connections, switches, and other components. In fact, for many installations it is advantageous to deploy an air or nitrogen purge system which creates a positive pressure within the enclosure in order to keep undesirable ambient elements, including sour gas, outside of it. As opposed to an open loop system that uses fans to draw ambient air into and push heat out of the enclosure, a closed loop system maintains isolation of the ambient air and permits the NEMA rating of the electrical enclosure to be maintained. Examples of closed loop cooling equipment for electrical enclosures include cooling units (also known as enclosure air conditioners or enclosure AC) and Air To Water Heat Exchangers.

Effective electrical enclosure cooling for environments where H2S gas is present must utilize a closed loop technique to ensure that sour gas is not introduced into the enclosure where it could harm wiring, electrical connections, switches, and other components. In fact, for many installations it is advantageous to deploy an air or nitrogen purge system which creates a positive pressure within the enclosure in order to keep undesirable ambient elements, including sour gas, outside of it. As opposed to an open loop system that uses fans to draw ambient air into and push heat out of the enclosure, a closed loop system maintains isolation of the ambient air and permits the NEMA rating of the electrical enclosure to be maintained. Examples of closed loop cooling equipment for electrical enclosures include cooling units (also known as enclosure air conditioners or enclosure AC) and Air To Water Heat Exchangers.

To avoid operations grinding to a halt, specifically those with flour and high particulate in the air, Pfannenberg’s PWS Series Air to Water Heat Exchangers are an ideal solution for efficient, trouble free cooling for electrical enclosures.. Use an existing glycol or cool water source already available in the factory to cool your electrical cabinets.

To avoid operations grinding to a halt, specifically those with flour and high particulate in the air, Pfannenberg’s PWS Series Air to Water Heat Exchangers are an ideal solution for efficient, trouble free cooling for electrical enclosures.. Use an existing glycol or cool water source already available in the factory to cool your electrical cabinets.

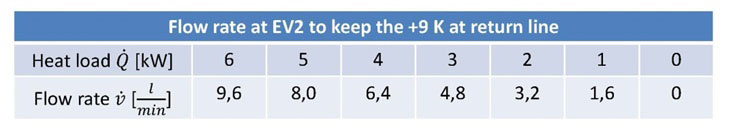

One of our machine tool customers needed a customized solution adapted to their customer’s environment allowing their industrial electronics to operate at optimal efficiency. Industrial cooling was needed for a grinding machine requiring cooling control accuracy. This is especially important as it significantly influences the grinding tolerance. The machine sands parts to remove all irregularities before sending them off for further assembly (gear manufacturing), the required control accuracy or hysteresis is up to +- 0.1 K in active units and up to +- 0.5 K in passive units.

One of our machine tool customers needed a customized solution adapted to their customer’s environment allowing their industrial electronics to operate at optimal efficiency. Industrial cooling was needed for a grinding machine requiring cooling control accuracy. This is especially important as it significantly influences the grinding tolerance. The machine sands parts to remove all irregularities before sending them off for further assembly (gear manufacturing), the required control accuracy or hysteresis is up to +- 0.1 K in active units and up to +- 0.5 K in passive units.