Unlocking Energy-Efficient Cooling with the DHS Hybrid Series

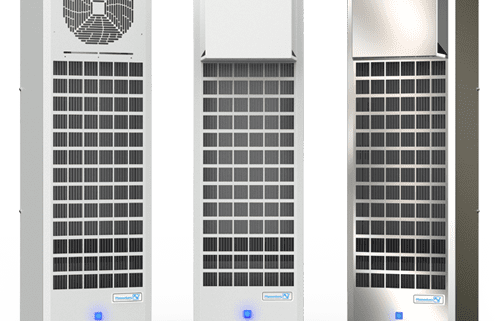

At Pfannenberg, we’re always pushing the boundaries of innovation, and our latest launch—the DHS Hybrid Series Cooling Units (DHS 34X1)—is no exception. Designed to optimize cooling efficiency while minimizing energy consumption, this cutting-edge system combines free cooling and active cooling to safeguard critical electronics. The result? Lower costs, reduced carbon emissions, and unparalleled reliability.

Why Hybrid Cooling Matters

The DHS-Series combines the best of free cooling and active cooling to radically impact an end-user’s energy consumption and carbon emissions while cooling their critical electronics.

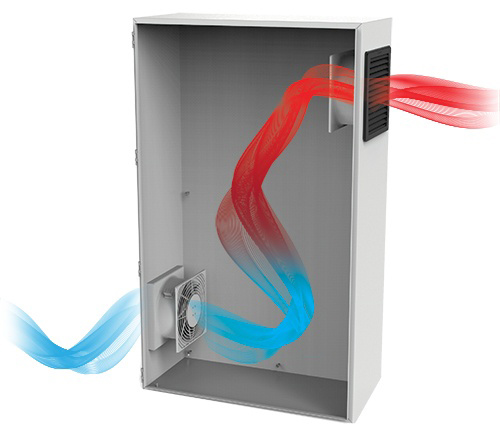

How does it work?

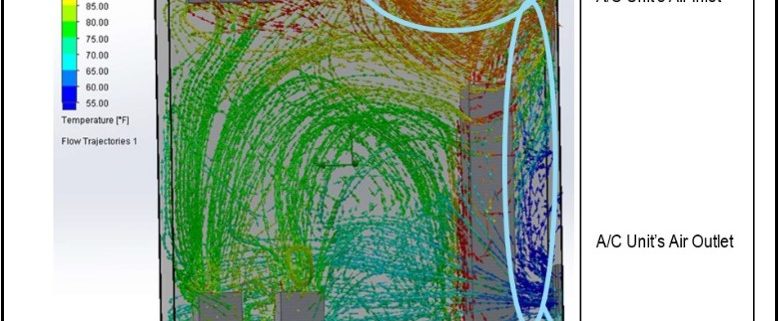

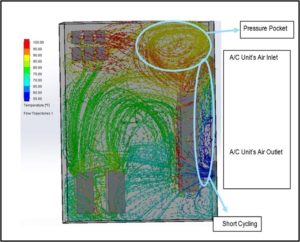

- Free cooling leverages cooler ambient air outside the enclosure to remove excess heat, reducing the need for additional energy consumption.

- Active cooling kicks in when necessary, using a compressor and refrigerant cycle to maintain the desired temperature.

By combining these two cooling methods, the DHS-Series optimizes energy use, providing an efficient and cost-effective solution for industrial environments.

Built for Maximum Efficiency & Versatility

The DHS-Series is designed to deliver maximum uptime and adaptability, ensuring critical electronics stay protected in a variety of settings. Here’s what makes it stand out:

- Dual Redundancy: A single unit provides both free and active cooling, reducing the risk of downtime.

- Universal Fit: Compatible with all full-sized enclosures for seamless integration.

- User-Friendly Display: An easy-to-read status display keeps monitoring simple.

Where Can You Use the DHS Hybrid Series?

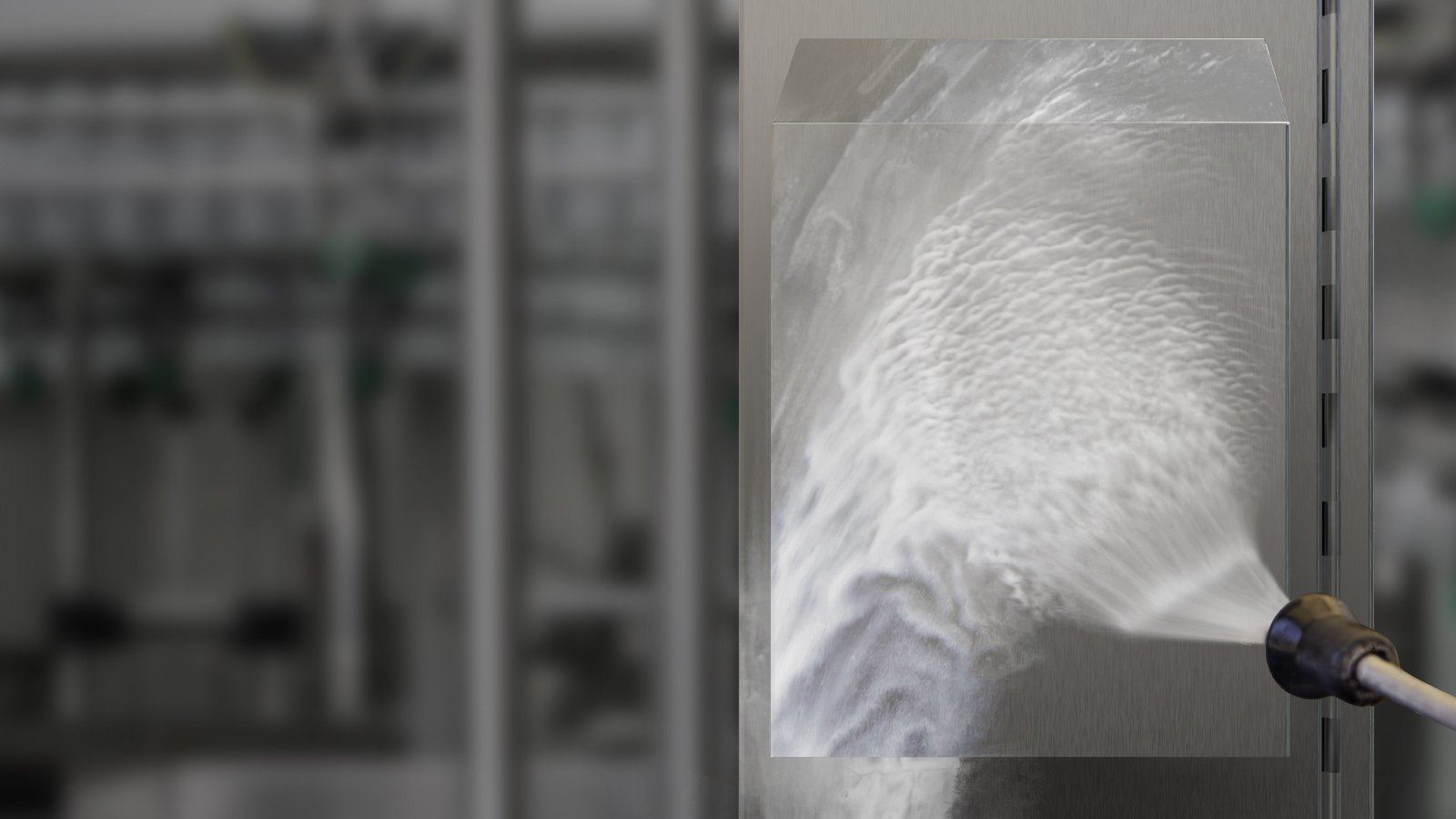

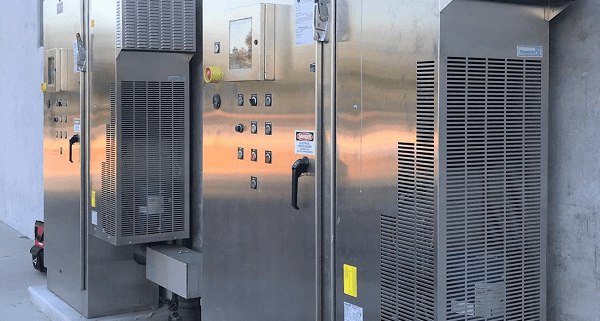

The Hybrid Series is ideal for locations with lower ambient temperatures, climate-controlled facilities, and operations that periodically run at partial capacity. This cooling solution is available in multiple configurations: Indoor (Type 12), Outdoor (Type 3R/4) and Washdown (Type 4X).

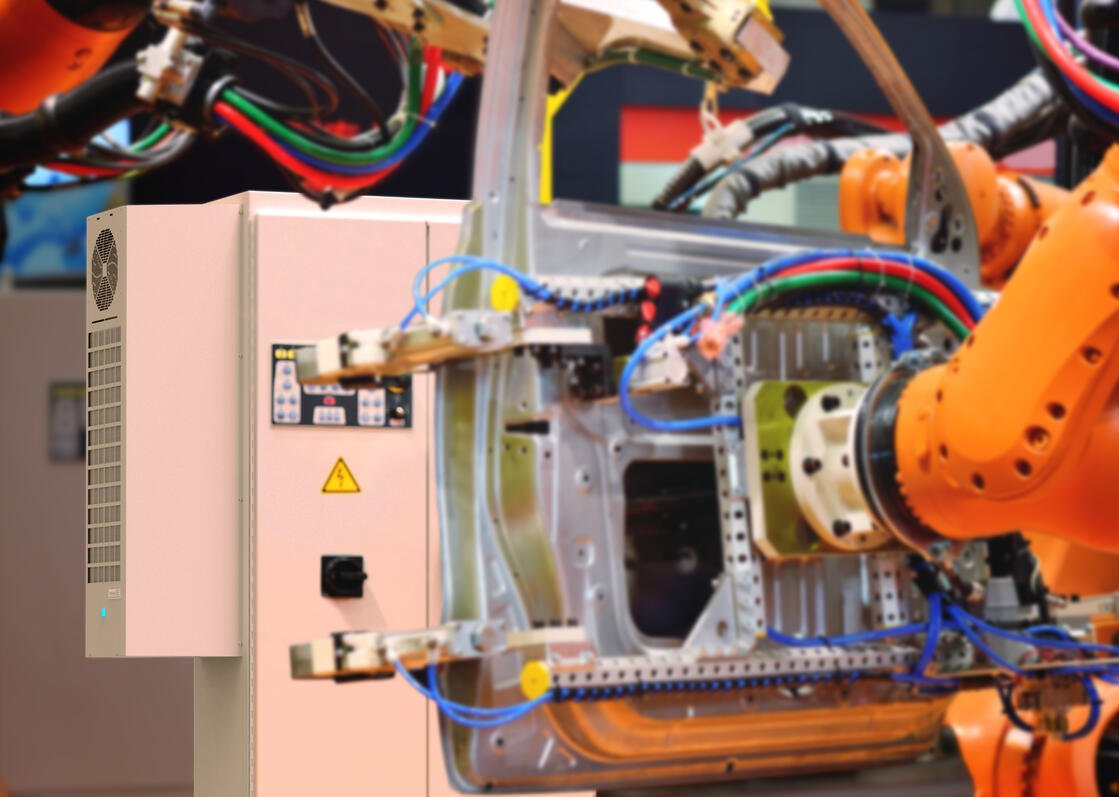

From automotive plants and warehouse automation to outdoor facilities, the DHS-Series is built to handle diverse industrial needs

Designed for the Future

The DHS-Series meets the highest safety and environmental standards, ensuring long-term reliability:

- UL 60335 certified for electrical safety compliance.

- Pre-gasketed design for quick and hassle-free installation.

- Environmentally conscious – designed to meet upcoming regulations on R-513A refrigerant usage.

The DHS Hybrid Series is more than just a cooling solution—it’s a strategic investment in energy efficiency, cost savings, and sustainability. To learn more, visit the DHS Hybrid Series (DHS 34X1) product page.