With Pfannenberg’s 3D-Coverage approach, the design of alarm and warning notification systems becomes easier and more reliable. The methodology takes advantage of effective performance in a given space rather than relying solely on nominal output data presented in typical specifications.

The goal of 3D-Coverage is to provide a visual representation of the effective range of the signaling device, lending justification to its successful implementation in the defined space. This valuable approach helps planners define alarm systems which guarantee effective safety warnings to personnel.

The information traditionally found in technical data sheets does not allow any conclusions to be drawn about the actual performance of a product in a given space. In an innovative approach, 3D-Coverage provides designers and safety officers with information about the size of the area effectively covered by a signaling device.

Perceptibility Counts

The major benefit of 3D-Coverage is that it takes factors such as ambient noise level and light intensity into account, focusing on the extent to which signals can be guaranteed to be heard and seen – an essential requirement for safe signaling solutions.

Ideal Sizing

By utilizing the 3D-Coverage concept, properly sized signaling devices are specified to ensure safety to personnel under the ambient conditions present – often leading to the most cost-efficient system in terms of number of units and installation expenses.

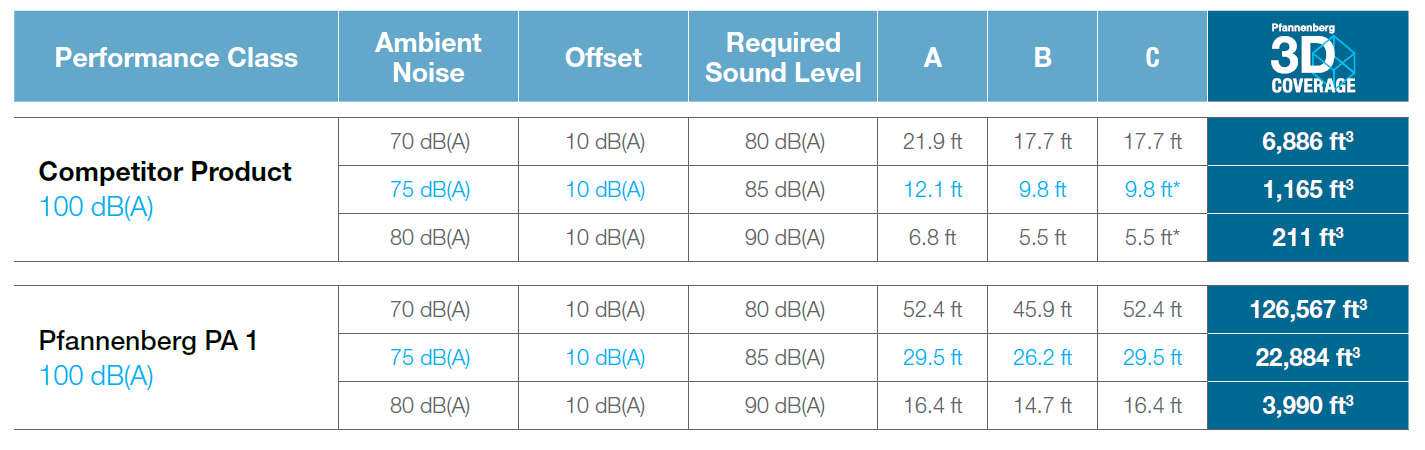

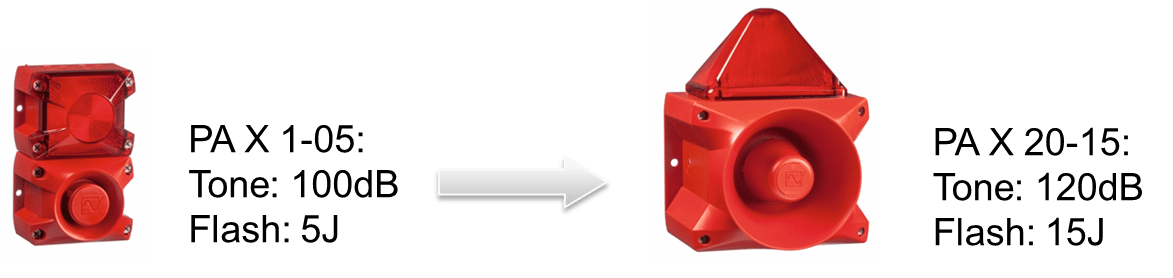

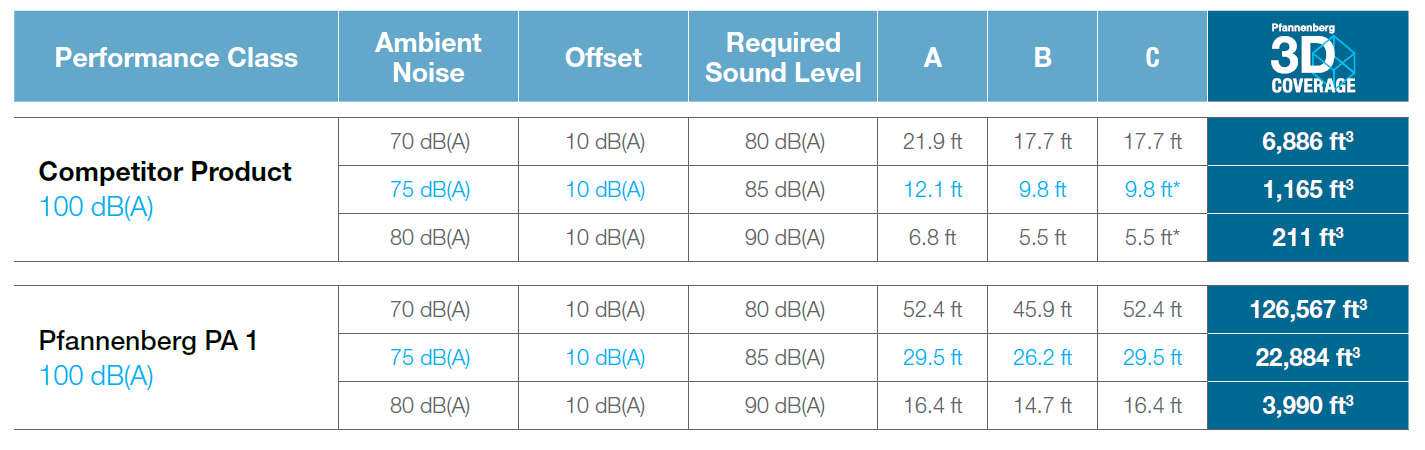

The differences in actual performance

3D-Coverage reveals the differences in actual performance which previously were not detected until it was too late. A frequent reason for dangerous under-sizing is the assumption that sounders of the same performance class have identical transmission characteristics in a given space. The adjacent diagram shows how very different the effective performance can actually be

Why Pfannenberg Signaling devices are better

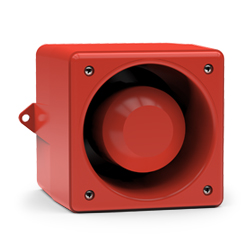

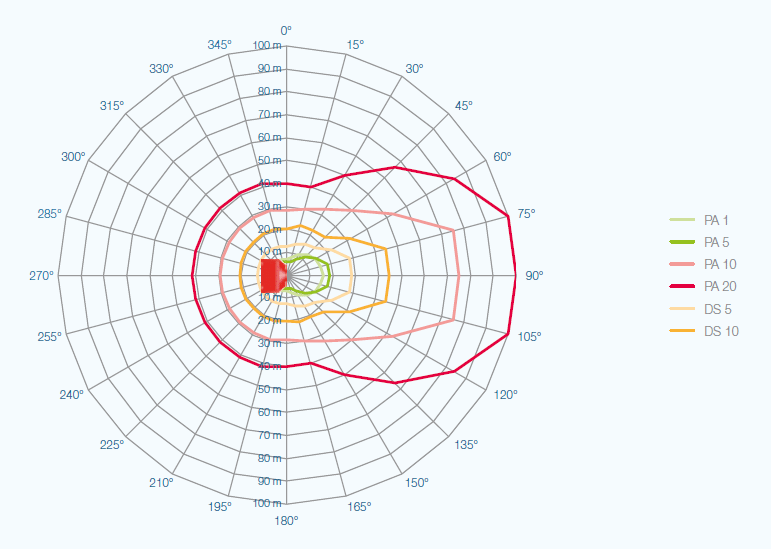

The performance of many sounder designs focuses on their capability in the axial (forward) direction, while inadequate output levels in the radial direction (side and downwards) is often overlooked. With the optimized design of Pfannenberg sounders, the sound propagation is distributed over a wider area in all directions.

Contact us for more information!

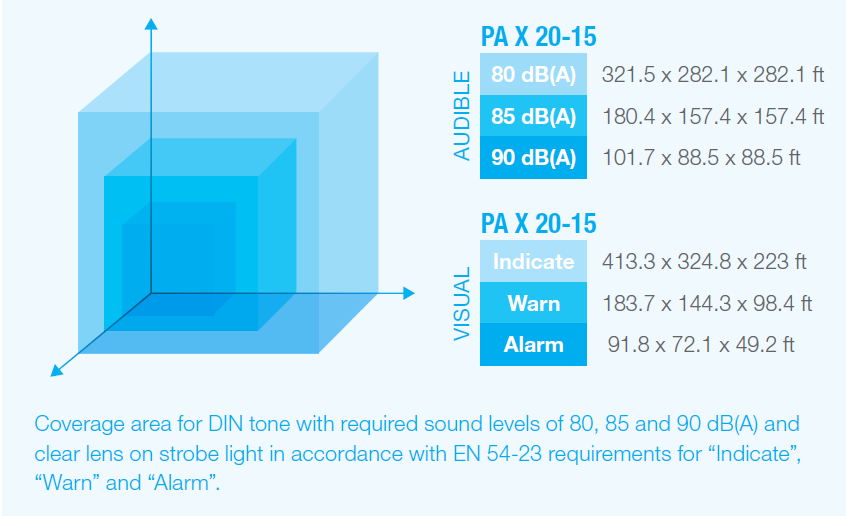

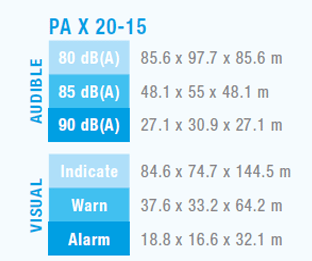

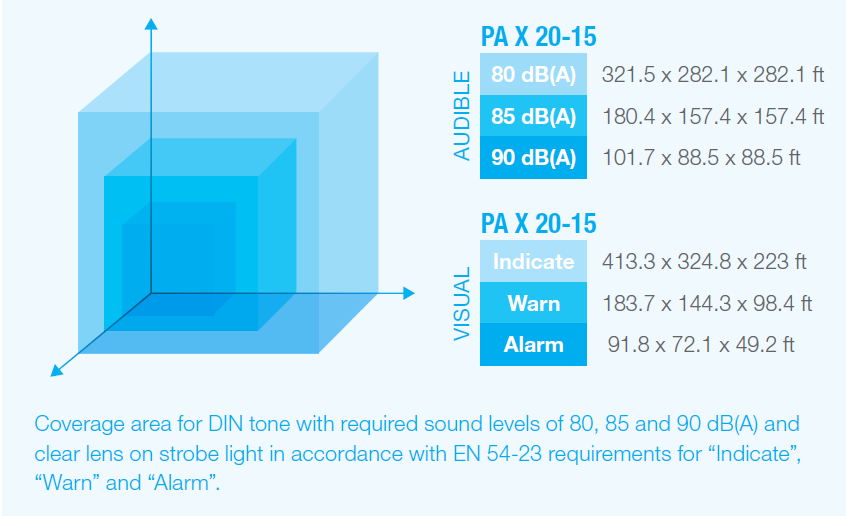

Example: Spatial Performance for Audible Notification

The perception of acoustic signaling devices is determined by many factors. In particular, ambient noise and the use of hearing protection must be taken into account. 3D-Coverage shows why.

Ambient Noise can influence Safety

Whether or not the audible signal from a sounder is successfully perceived is not just dependent on the output sound level generated and technology used to create the alarm signal. Ambient noise levels and sounder placement location are crucial elements that should not be overlooked.

The adjacent example illustrates the effect on coverage volume of an 100 dB(A) audible signaling device due to a 10 dB(A) change in ambient noise level. Increasing from 75 dB(A) to 85 dB(A) shows that the warning signal will not be successfully perceived.

The 3D-Coverage values show that the effective covered area is significantly reduced when the ambient noise level rises. If the alarm system designer does not take all aspects into consideration, the consequences can spell danger for people in the surrounding area.

Effective Coverage – Guaranteed

Every aspect of the alarm system design process is susceptible to errors. Incomplete system requirements, inattention to environmental factors, insufficient product specifications, and lack of actual signal coverage dimensions can all contribute to an inadequate safety mechanism. The 3D-Coverage approach planners users avoid errors and achieve the optimum solution.

1. Defining Requirements

Various standards and codes are in force which influences the planning of signaling solutions. However, many of them are merely superficial.

For example, the EU Machine Directive stipulates that machinery manufacturers must put in place suitable measures to minimize the risks of operating the machinery – but if signaling is a potential solution, there are no defined requirements for the performance of such devices. Since the machinery builder is responsible for mitigating operational risks, it is imperative to utilize signaling devices which offer sufficient effective coverage to operators and nearby personnel.

The 3D-Coverage approach gives them the answers needed to deploy adequate signaling to ensure that warning signals are perceived. With fire alarm systems, performance requirements for signaling devices have been formulated. To ensure adequate alarm perception, EU directives such as EN 54-23 require that ambient conditions within the space in which the signal is to be heard or seen are taken into consideration. Utilizing the 3D-Coverage approach, planners and system designers are not only assured of adequate notification appliance performance since they can also gain confidence in designing the most cost-effective solution.

2. Taking Environmental Conditions Into Account

Many harmful situations, including fire and gas leaks, chemical spills, machinery hazards, moving equipment dangers, and other workplace safety concerns can be effectively mitigated only when signaling systems are properly designed. An examination of the space to be protected produces vital information that must not be overlooked when planning for safety.

Where are people situated? What environmental influences and risks are they exposed to? What are the particular features of the building? It is essential that these issues be considered at the planning stage in order to ensure the safety of all personnel within the space in which the alarm signal must be seen and heard.

Unfortunately, in many circumstances, the environmental conditions surrounding the application are not thoroughly examined or understood. For example, an ambient noise level that is assumed to be lower than it actually is will inevitably result in signal tones that are difficult to hear or cannot heard at all.

When the 3D-Coverage approach is utilized, environmental factors are taken into consideration at the very start of the planning process. Not only does this represent a more cost-effective procedure, but more vitally, the resultant system design is safer for personnel and guaranteed to meet with final approvals.

3. Comparing Product Information

Information supplied on technical data sheets alone often results in unrealistic assumptions about the actual performance of signaling devices. Details such as the transmission distance and coverage envelope must be obtained if they are to be taken into consideration when planning alarm systems.

For the 3D-Coverage approach, Pfannenberg supplies transparent and unambiguous information about the performance of a product in a given space, taking into account defined environmental conditions

4. Ensuring Optimal Sizing

It is only when all factors, such as environmental influences, local codes and requirements, and true overall performance of the signaling devices to be used are understood, that a properly sized and effective alarm notification system can be designed.

Possible consequences of inappropriately designed signaling systems include under-sizing, over-sizing, safety to personnel, cost overruns, system non-acceptance, and loss of machinery and assets.

Under-sizing, or using too few or less-capable devices, can be the result of relying solely on published specifications for notification appliances and not taking environmental conditions into account. This can lead to a safety risk or non-acceptance of the system by the local authority having jurisdiction (AHJ). When re-designs are mandated, costs will increase.

Over-sizing, or using too many devices, can unnecessarily raise costs for materials, installation labor, and maintenance. A holistic approach at the planning stage is the only way to ensure effective alarm notification, safety, and design efficiency. With 3D-Coverage, Pfannenberg emerges as the logical choice for helping planners and system designer fulfill these requirements.

The Advantages

3D-Coverage offers transparency in an area where incorrect assumptions and ambiguous performance values can have dangerous consequences. Because it delivers explicit data, 3D-Coverage provides certainty for those involved in creating signaling systems and safety for personnel who occupy spaces in which these systems are used.

Clear information about the coverage volume

3D-Coverage focuses on how signals are perceived in a given space. For example, by aking ambient noise into account, 3D-Coverage offers reliable data about the effective coverage area provided by an audible notification appliance.

The ideal solution for safety signaling

With explicit information about the effective coverage volume, 3D-Coverage provides maximum reliability in both the type and quantity of visual and audible signaling devices selected for alarm systems.

Confidence in design, costing, and acceptance

With 3D-Coverage, the optimum signaling systems are assured, leading to immediate acceptance and avoidance of potentially costly redesigns.

Prevents incorrect sizing

Using 3D-Coverage, system planners and designers are assured of using the proper number and type of signaling devices that are needed in order to safely warn personnel of dangers in the entire notification space.

Getting it right the first time

When systems are properly designed from the beginning, unforeseen and costly redesigns and delays are avoided. 3D-Coverage ensures that projects are properly designed.

Protecting man, machine and the environment

The safety of personnel and operating systems are crucial to the success of any organisation. 3D-Coverage makes it easy to be certain that protection systems are effective and efficient.

Contact us for more information!

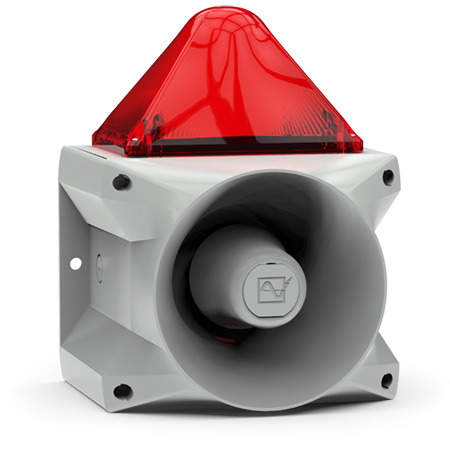

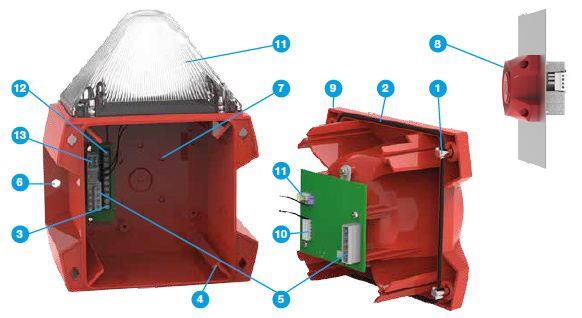

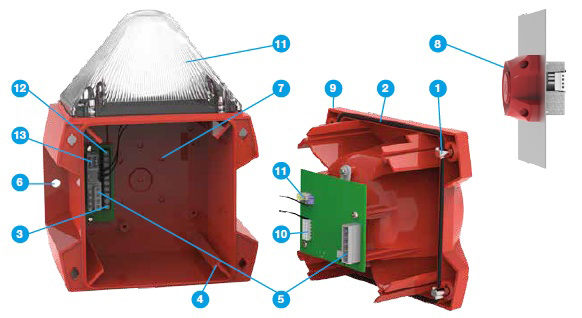

> Visible field of 180° x 360°

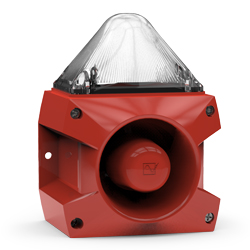

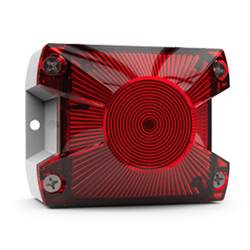

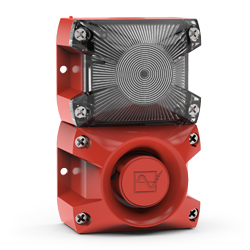

> Visible field of 180° x 360° > Enhanced safety with alarms that are seen and heard

> Enhanced safety with alarms that are seen and heard Pfannenberg’s PATROL and PYRA visual/audible alarms offer extensive certifications including UL, GL and CE in support of worldwide requirements.

Pfannenberg’s PATROL and PYRA visual/audible alarms offer extensive certifications including UL, GL and CE in support of worldwide requirements.

Pfannenberg’s PKS 3000 Series Air to Air Heat Exchangers use a revolutionary next generation cooling technology that out-performs conventional heat exchangers and/or heat pipe solutions. One of the best technologies to use when there is a temperature difference between the internal target temperature and the surrounding temperature (∆T≥10°C) is air to air technology.

Pfannenberg’s PKS 3000 Series Air to Air Heat Exchangers use a revolutionary next generation cooling technology that out-performs conventional heat exchangers and/or heat pipe solutions. One of the best technologies to use when there is a temperature difference between the internal target temperature and the surrounding temperature (∆T≥10°C) is air to air technology.

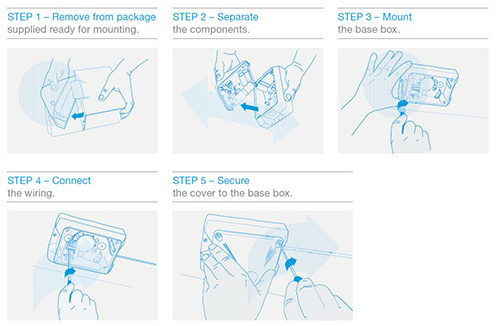

Pfannenberg industrial alarms with visual and audible notifications come with a standard 10-Year Warranty, guaranteed in protecting man, machine, and the environment.

Pfannenberg industrial alarms with visual and audible notifications come with a standard 10-Year Warranty, guaranteed in protecting man, machine, and the environment.