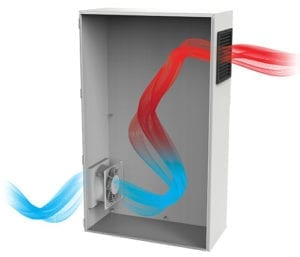

What are filter fans?

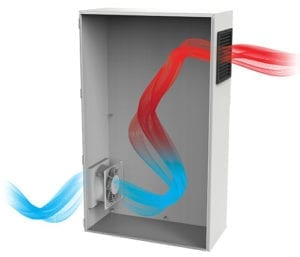

Filter fans protect electrical enclosures from external environmental damage. From heat control to mitigating the ingress of liquid and solid objects, filter fans provide another layer of protection for the electrical equipment housed within enclosures. Filter fans protect critical equipment by reducing thermal load and filtering out airborne particles larger than 5 microns. The dual fan and filter composition keeps electrical equipment running at optimal temperatures while mitigating the amount of dust and other particulate matter from causing buildup and damage.

When selecting a filter fan for an enclosure, it’s important to consider the application’s heat load, optimal temperature, and environmental conditions in which it will be operating. Environmental considerations are particularly important for outdoor enclosures, as rain, snow, ice, and sunlight all pose risks to electrical equipment.

Challenges for outdoor applications

Filter fans are necessary for a wide range of outdoor electrical equipment. Some applications, however, require intentionality and extra consideration when choosing the appropriate filter fan. These include irrigation pump panels, water and waste water, lighting control boxes for traffic signals or fields and stadiums, outdoor communication and information technology structures, energy storage and charging systems (such as in electric vehicles), and transportation systems, including bridges, toll stations, and electrical rail equipment.

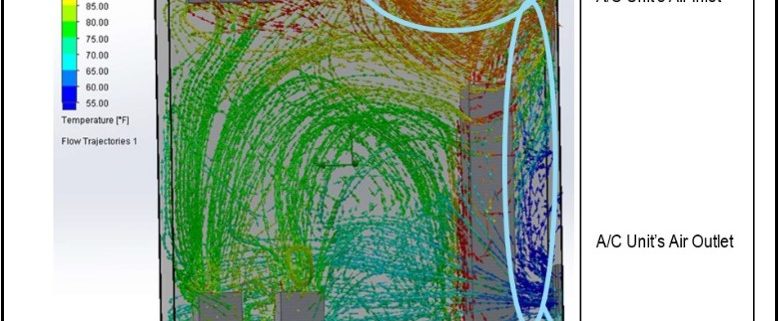

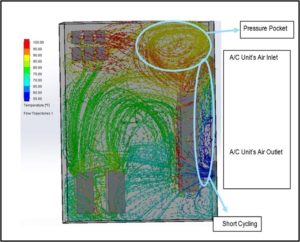

When properly designed and integrated, outdoor filter fans can provide an energy efficient solution for heat load maintenance while also protecting enclosures from dust, ice, water, and sunlight. However, many filter fans on the market do not effectively protect critical electrical equipment. When improperly designed, filter fans can be subject to ice and dust buildup or damage from UV radiation and rainwater. These conditions can cause short circuiting within the enclosure. While there are workarounds for water infiltration, such as adding a rainhood, these additional steps increase space requirements and initial investment costs.

Tips for selecting the correct filter fan for outdoor applications

Given these challenges, there are some tips to keep in mind when selecting a filter fan for an outdoor electrical enclosure.

Consider heatload and environment

Selecting an outdoor filter fan begins with determining the application’s heatload and airflow requirements while considering environmental exposure. Electrical enclosures in dry, hot weather require different filter fan needs than those used in areas with snow, ice, and highly variable temperatures. For applications where environmental conditions cannot be determined ahead of time, a filter fan that can accommodate each of these possibilities is best.

While determining application needs, it is beneficial to consult with an expert to help determine specific risk factors. An expert can help with considerations around which airborne particulates are present and if they are corrosive, as well as what ambient temperatures can be expected and how direct or indirect sunlight can affect operating temperatures.

The Pfannenberg Outdoor Rated Filterfan® (NEMA 3R rated) is designed for outdoor weather where direct sunlight and extreme weather, like rain and ice formation, are important factors. This filter fan utilizes UV-resistant plastics to prevent premature degradation from direct sunlight. Additionally, the filter fan’s design protects against the ingress of falling dirt, rain, sleet, snow, and even external ice formation.

The Pfannenberg Outdoor Rated Filterfan® (NEMA 3R rated) is designed for outdoor weather where direct sunlight and extreme weather, like rain and ice formation, are important factors. This filter fan utilizes UV-resistant plastics to prevent premature degradation from direct sunlight. Additionally, the filter fan’s design protects against the ingress of falling dirt, rain, sleet, snow, and even external ice formation.

Weigh maintenance needs

Filter fans generally require little maintenance outside of regular filter replacement. However, it is crucial to change the filter as specified by the manufacturer as filter clogs reduce airflow, causing extra strain on the fan and increasing the potential for overheating.

Well-designed filter inserts, including the filter for Pfannenberg’s Outdoor Rated Filterfan® described above, provide longer service life. Pfannenberg’s fluted filter-mat enables longer mean time between maintenance, delivering three times longer service life than standard designs. It accomplishes this with its increased dust holding capacity. As a result, the need for service is reduced, saving maintenance time, costs, and stress, which is especially helpful for electrical enclosures located in remote areas.

Balance protection, airflow, and initial investment costs

Filter fans for outdoor applications require a design that balances airflow optimization with low initial investment. A filter design that minimizes maintenance needs should also ensure unrestricted airflow throughout the fan’s service life. However, it must do so without compromising on water and dust protection capabilities. Combining a filter that fits these needs with a filter fan housing design that does not require metal rain hoods, achieves an excellent balance of protection, airflow management, and minimizing upfront costs.

Conclusion

Filter fans are critical for protecting electrical equipment from overheating, water, and airborne debris so the equipment can run safely and efficiently. In outdoor environments, this task is particularly challenging. Finding a filter fan suitable for outdoor environments without significant drawbacks requires careful research. By considering heatload, environmental conditions, and maintenance needs before selecting a filter fan, it is possible to keep costs low. In applications ranging from pump panels and lighting control boxes to communication technology and energy storage systems, well-designed filter fans keep outdoor electrical equipment functional and safe.