By Adam Wells, Solutions Engineer, Pfannenberg USA

Cooling systems help achieve better battery performance, durability, and safety

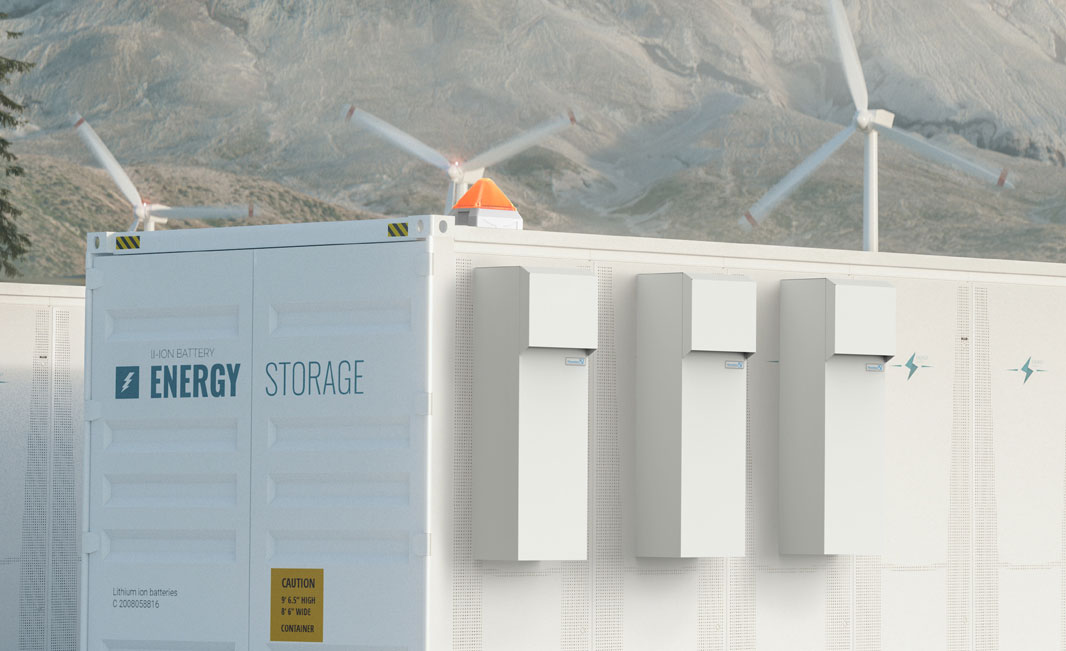

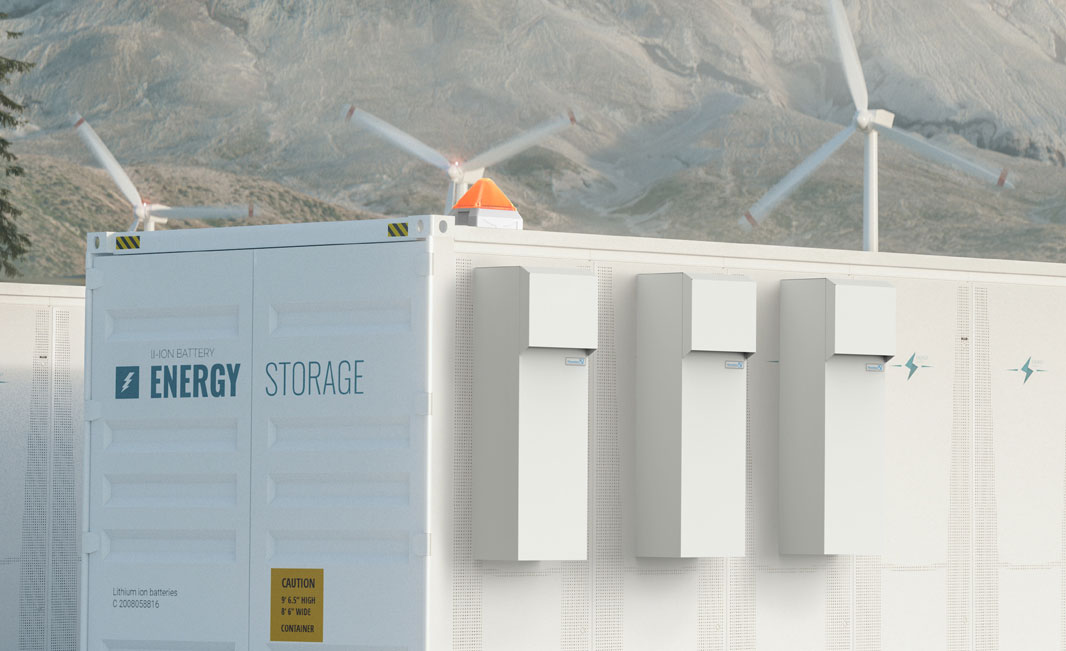

Battery energy storage systems (BESS) are helping to transform how the world generates and consumes electricity as we transition from large-scale fossil fuel plants to renewable sources. The market for BESS is projected to grow at a compound annual growth rate (CAGR) of 30 percent from 2023-2033 according to IDTechEx. What’s more, the global cumulative stationary battery storage capacity is expected to reach 2 terawatt hours (TWh) within ten years.

What’s the catch? The market is challenged by the basic fact that electrochemical energy storage is notoriously vulnerable to overheating, risking sudden fire and explosion, in addition to causing degraded performance and shortened lifetime. Cooling systems are critically important for BESS, providing the thermal stability that is crucial for battery performance, durability, and safety. If applied correctly, the solutions will reduce battery degradation and damage, and minimize downtime.

Thermal Stability and Uniform Temperature

In general, it is best to keep batteries at a moderate, consistent temperature to ensure their optimal performance and longevity. Exposure to extreme temperatures, either hot or cold, can damage batteries and cause hazardous events.

The specific temperature range that batteries require to operate safely varies depending on battery type and design. While new battery technologies are being developed every day, lithium-ion batteries continue to dominate energy storage systems due to falling battery costs and increased performance with less weight and space requirements giving better energy density compared to other battery types. It is likely that lithium-ion will continue to be the most common BESS technology for the foreseeable future.

According to the US National Renewable Energy Laboratory, the optimal temperature range for lithium-ion is between 15 °C and 35 °C. An ambient temperature of about 20°C or slightly below (“room temperature”) is ideal; if a battery operates at 30°C, its lifetime is reduced by 20 percent. At 40°C, the losses in lifetime approach 40 percent, and if batteries are charged and discharged at 45°C, the lifetime is only half of what can be expected at 20°C.

It is also equally important to maintain uniform temperature throughout the system. Avoiding hot spots is crucial to preventing damage and mitigating the risk of triggering a chain reaction that leads to catastrophic thermal runaway.

Causes of Battery Overheating

One key factor contributing to overheating is use in applications that require rapid charging/ discharging. These are referred to as having a high C-rate, defined as the charging or discharging current divided by the capacity (the amount of energy the battery can hold). Applications with a high C-rate and frequent cycling generate more heat.

Another factor is high ambient temperature, which can damage batteries in several ways. Elevated temperatures lead to an increased rate of side reactions, causing attrition of active material and resulting in a build-up of resistance at the electrode surface. Operation of lithium-ion batteries at high temperatures will also accelerate the aging process and lead to performance degradation.

Paradoxically, low ambient temperatures can cause more problems with internal overheating than high ambient temperatures. Cold temperatures can result in viscosity changes in the electrolyte that lead to sluggish ion transport, resulting in higher resistance and heat generation.

Designing an Optimal Cooling Solution – Liquid or Air Cooling?

BESS thermal management solutions include liquid and air cooling; the optimal solution depends primarily on the application’s C-rate and environmental conditions. The most demanding thermal management applications, such as large-scale BESS installation and high C-rate applications, require active liquid cooling. Smaller installations with low C-rate applications can be safely and efficiently operated with air cooling.

Liquid cooling

Liquid cooling is extremely effective at dissipating large amounts of heat and maintaining uniform temperatures throughout the battery pack, thereby allowing BESS designs that achieve higher energy density and safely support high C-rate applications.

allowing BESS designs that achieve higher energy density and safely support high C-rate applications.

Multiple versions of chillers are available to optimize the layout of the cooling system. For example, Pfannenberg offers two layout options: A stand-alone chiller can be placed inside the BESS. Each unit provides up to 12kW of cooling, and multiple units can be easily combined to support the highest cooling load requirements. Alternatively, a compact version is designed to be mounted outdoors on the cabinet door, for a small footprint that allows easy integration inside battery cabinets and enclosures. Both solutions safely operate between -25 and +50°C and offer up to 800 V DC power supply to directly connect with the battery system, all while not needing any power conversion.

Air cooling

Air cooling systems provide a cost-effective cooling solution for smaller stationary energy storage systems operating at a relatively low C-rate.

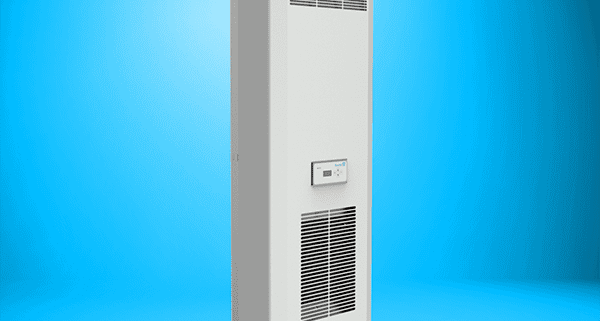

For example, Pfannenberg’s DTS Cooling Unit seals out the ambient air, and then cools and re-circulates clean, cool air through the enclosure. The closed loop design isolates the external ambient air from the internally conditioned air eliminating the risk of contaminants entering the cabinet. Thehermetically sealed compressor guarantees 100 percent cooling capacity efficiency.

For applications where the ambient air is always cooler than the temperature required inside the enclosure, filter fans, which use natural convection of the air to circulate air and dissipate heat, are extremely cost-effective.

Energy storage plays an important role in the transition towards a carbon-neutral society. BESS systems depend on cooling systems that provide the thermal stability that is crucial for battery performance, durability, and safety. and if applied correctly, will reduce battery degradation and damage, and minimize downtime.