Pfannenberg cooperates with G2K to provide safety solutions in the fight against COVID-19

AI-based data management for access control of production sites and supply chains.

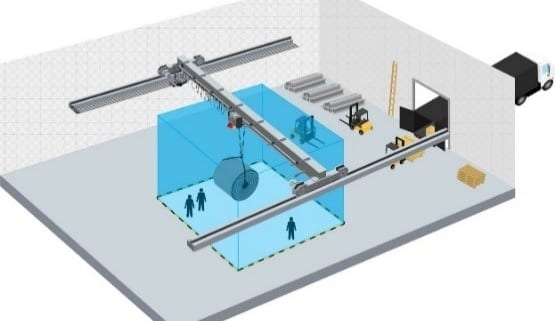

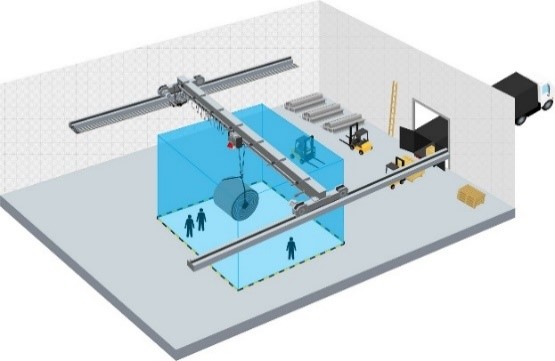

Due to the high risk of infection with COVID-19, production plants are threatened with the failure of entire production lines as well as the destruction of finished products through infection, or simply suspicion. This can quickly lead to huge economic damage and loss of reputation for society as a whole. An effective method of preventing a breakdown and possible economic damage is secure access control for employees, suppliers and service technicians.

Prevent production downtime safely with COVID-19

The software manufacturer G2K has developed a platform that monitors access control by, among other things, thermal camera-based body temperature measurements and algorithm-based analysis of video streams. If a camera or a sensor detects any sign when an area is entered, such as fever symptoms or the lack of wearing a face mask, the multicolour LED light from Pfannenberg functions like a traffic light: a red signal indicates that access is denied, whereas a green signal indicates that no irregularities have been detected and access is granted.

G2K relies on RGB LED light from Pfannenberg

The advantages of an RGB light are obvious: several colours can be displayed by just one device. In addition, the PYRA® LED RGB not only offers various installation options, but can also be installed quickly thanks to cable entries on all sides thanks to its Plug&Play system. A high IP protection allows its use in almost every application, but especially in the field of access control. The essential advantage of this Signaling LED Solution is the option for direct control via the alarm output of the camera, this considerably reduces the number of system components and leads to a cost-efficient solution. Users can choose between different signaling modes and high performance and visibility, even in daylight, is always guaranteed thanks to the ultra-bright LED technology.

Faster, more hygienic and more accurate than manual actions

This technology is a market-ready option for real-time detection of symptoms of fever, congestion or lack of facial coverage. As a result, access processes are monitored more quickly, hygienically and accurately than with purely manual measurements.

Access criteria and measures individually adjustable

Users can individually determine which access criteria are measured or which ones grant or deny access: For example, it is possible to measure fever values, check whether a mouth-nose mask is worn or even set a capacity limit on persons.

In the event of an alarm, efficient and targeted reactions such as refusal of admission in the event of overcrowding can be implemented by means of automated lists of measures.

A connection to the HR system is also possible in order to obtain a real-time overview of all relevant key figures and, for example, to trace chains of infection or take certain measures.

Any Questions? Contact our Signaling Experts Now!

In 2021, IFC refrigeration systems that use ammonia refrigerant, along with the buildings where they are used, must comply with IIAR–2 for system design and installation, IIAR-6 for maintenance and inspection, and IIAR-7 for operating procedures. Though these standards help ensure safety and efficacy, guidelines for selecting the correct audible and visual alarms can be buried deep within this regulatory code and, accordingly, these standards can be difficult to adhere to.

In 2021, IFC refrigeration systems that use ammonia refrigerant, along with the buildings where they are used, must comply with IIAR–2 for system design and installation, IIAR-6 for maintenance and inspection, and IIAR-7 for operating procedures. Though these standards help ensure safety and efficacy, guidelines for selecting the correct audible and visual alarms can be buried deep within this regulatory code and, accordingly, these standards can be difficult to adhere to.