Ammonia Gas Detection in Food & Beverage Facilities

Alarm and Warning Devices to Notify Personnel Regarding Dangerous Gas Leaks

Ammonia leaks are pretty uncommon, but when one does occur – the results could be lethal. Ammonia gas is very toxic and flammable. Typically ammonia can be detected by smell (a strong and pungent odor), but it is a colorless gas.

The human nose can detect an ammonia leak with exposure between 5-20 ppm. With exposure 25 – 1,000 ppm, employees with have teary eyes, difficulty breathing, and the instinct to flee the area. The time exposed and the amount of ammonia the employee(s) are exposed to, determines various effects on the human body – ranging from a slight smell to teary eyes and unable to breathe, possibly death.

There are both, caustic and hazardous versions of the chemical. In most large scale food and beverage facilities one would find the caustic version of the chemical used to aid in refrigeration. The chemical can also be mixed with water (ammonia hydroxide) to create a multipurpose cleaning agent.

Majority of these leaks occur in the mechanical room containing the refrigeration compressors of the facility. Most ammonia used within a plant is used for refrigeration. Why do so many food and beverage manufacturers use ammonia refrigeration in their facilities when it is potentially dangerous? Ammonia refrigeration is one of the most energy efficient and cost effective ways of storing and processing food and beverage product.

Food and beverage ammonia refrigeration applications include:

- Cooling of beverages, beer, wine

- Freezing of process foods

- Freezing of ice cream

- Cooling of dairy products

- Freezing and refrigeration of meats

Unlike fire evacuations and being told to exit to the closest door… with ammonia leaks, employees are asked to wait for specific instructions in where to exit. Sometimes the closest exit may not always be in the right direction, away from the gas leak. Ammonia evacuation signals must be different from fire alarms to avoid confusions. All employees must be trained on the difference in the alarms.

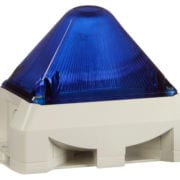

Pfannenberg has had experience in protecting personnel from gas and vapor leaks. Our robust and multi-toned flashing sounders, offer 80 different tones – perfect for alerting and protecting personnel. Due to the large signaling coverage provided by each alarm, the amount of signaling devices required is significantly reduced. This supports an application that is economical while ensuring industrial safety.

Generally speaking, a blue light/strobe is a warning color used for toxic gas leaks, and red is used as a warning color for combustible gas leaks – but users can use any color unless directed by a local code or law. Blue tends to be the favorable color used in Ammonia gas leak alarms.

Common refrigeration alarms alert people about high concentrations in a room where they should not go. Our signaling will extend this warning to other operating employees in the facility who can be immediately alerted to a problem so corrective action can be immediately undertaken.

Pfannenberg industrial alarms with visual and audible notifications come with a standard 10-Year Warranty, guaranteed in protecting man, machine, and the environment.

Click here to learn more about Signaling Technology and Solutions!

Topics: Industrial Safety & Signaling Solutions, Food & Beverage