X-Series Cooling Units

The X-Series cooling units represent a significant advancement in thermal management technology. Designed for energy-efficiency with precise temperature control through inverter technology. Notably, the X-series units are interchangeable with the Green Series and older Pfannenberg cooling units, thanks to their consistent installation cut-out dimensions. This interchangeability, coupled with quick assembly properties, facilitates the easy implementation of energy-saving cooling solutions even during ongoing production. With cooling capacities ranging from 1,000 to 4,500 W and the inclusion of a premium controller, these units are engineered to deliver powerful, accurate, and energy-efficient cooling.

Why Choose Pfannenberg X-Series Cooling Units?

Flexible

Flexible

Utilizing inverter technology, each unit covers a wide range of cooling capacity making each unit highly versatile.

Connectivity Ready

Connectivity Ready

Comes standard with RS485 interface to enable communication via Modbus RTU protocol.

Quick Installation

Quick Installation

Cutout is compatible with other Pfannenberg units for easy upgrade. Available in both recessed mount and side mount to save floor space.

Energy Efficient

Energy Efficient

The variable speed compressor will adjust according to the application requirement using less energy compared to fix speed compressor. The variable speed components combined with Pfannenberg years of experience optimizing the control algorithm leads to significant energy savings for customers.

Precise Cooling

Precise Cooling

Designed for precision cooling with accuracy of +/-0.1 K (0.2degF).

Multiple Mounting Styles

Multiple Mounting Styles

Available in both recessed mount and side mount to save floor space.

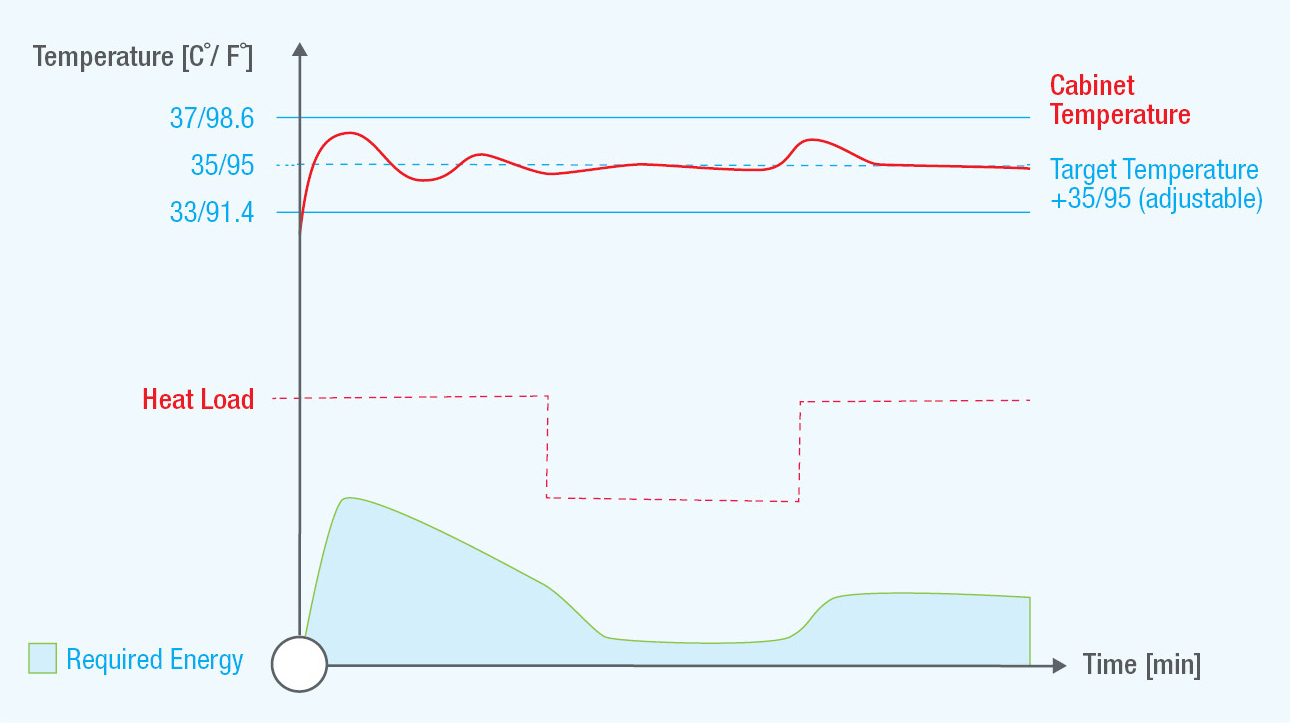

Precision Cooling for Efficiency

Inverter technology combined with years of experience in control algorithms eliminates the temperature spike within the cabinet seen in single speed compressor cooling units. This system provides more consistent cabinet temperature protecting the sensitive components inside (refer to the solid red line). The inverter technology allows the cooling unit to operate at partial load by only cooling to the heat load (red dotted line) inside the cabinet to reduce energy consumption (refer to green line).