Pfannenberg Process Chillers used for Cooling Edge Banding Machines

Duravit is a leading manufacturer of porcelain bathroom fittings, making top-grade bath furniture at their Schenkenzell site. Pfannenberg was contacted to replace a 12 year old process chiller for the subsystem switchgear cabinets used with their edge banding machine.

Needs Assessment

Duravit consulted with their engineering firm for advice on upgrading their equipment. This same engineering firm was also a Pfannenberg Competence Centre (PCC) partner. Pfannenberg business development manager for chillers was brought in on-site to meet and review the necessary requirements to cool both the cabinet and machinery.

At the end of this process the decision was clear: a Pfannenberg EB 60 WT packaged chiller with a custom configuration was the ideal solution for cooling the switchgear cabinets used with the edge banding machine.

“We already had some Pfannenberg process chillers in use at various places in the Schenkenzell plant. When the existing unit for our edge banding machine had to be replaced, it was clear that we needed a new solution. In the end we chose the energy-efficient chiller solution from Pfannenberg due to our good experience with them in the past.”

Reliable cooling capacity

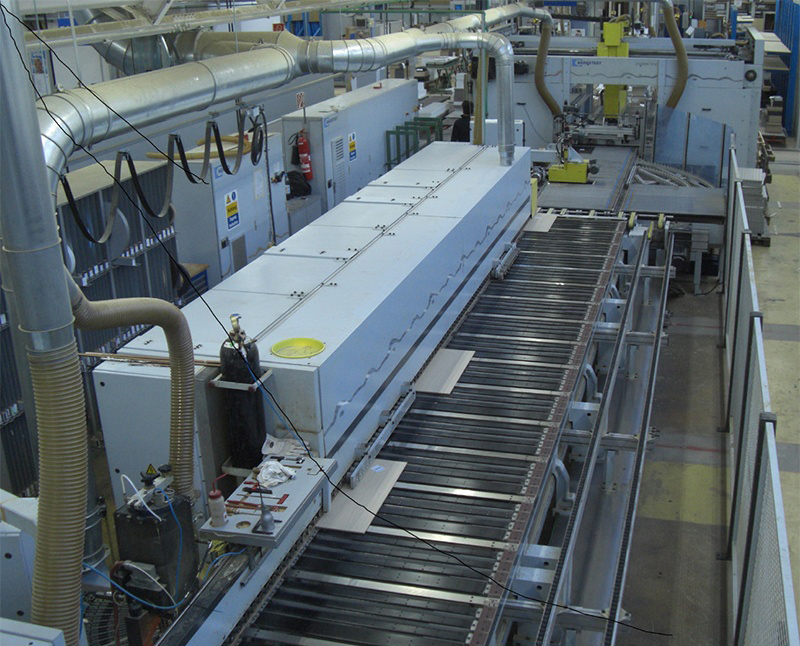

The edge banding machine in Duravit’s Schenkenzell plant runs about 4,500 passes a day.The edge banding machine feed unit glues edging to bath furniture. With double-sided gluing and four sides to be handled, each item passes through the machine twice – and thousands of items are processed per day.

Due to high dust levels in furniture manufacturing, a closed-circuit cooling system with water refrigerant is the ideal solution for thermal management of switchgear cabinets. In the summer the ambient temperature can rise to 40°C when bright sunlight shines through the glass roof of the Schenkenzell factory building.

This makes a reliable, high-performance cooling solution especially important. The EB 60 WT unit has a rated capacity of 6 kW and delivers a continuous flow of chilled water. The water is used to cool the electronic components inside the switchgear cabinets distributed over the 50m length of the machine, including variable speed drives and controllers. The modular switchgear cabinets are integrated into the machine as pull-out subcabinets.

Individually adaptable and easy to service

A special feature of Pfannenberg’s EB series is their modular architecture, which makes them easy to adapt to individual applications. In addition, Duravit opted for an special high-performance pump with rated pressure up to 5 bar, instead of the standard 3 bar with 35 litre flow volume in 50 Hz operation.

A special feature of Pfannenberg’s EB series is their modular architecture, which makes them easy to adapt to individual applications. In addition, Duravit opted for an special high-performance pump with rated pressure up to 5 bar, instead of the standard 3 bar with 35 litre flow volume in 50 Hz operation.

The chiller’s flow monitor keeps an eye on how much water is flowing through the cooling circuit, and the thermostat measures the water temperature.

If the cooling water flow is too low (risk of condensation) or the refrigerant temperature is too high (risk of overheating), the chiller sends an alert to the machine’s operator console so that damage to the electronic components of the edge banding machine can be avoided and high machine reliability can be achieved.

The refrigerant tank is also monitored by a sensor so that service personnel are informed promptly when the tank needs refilling. Pressure sensors monitor the air flow through the inlet filter. This enables preventive maintenance and reduces the need for wear parts.

The alerts are made possible by chiller’s ability to exchange control signals with the edge banding machine through the Harting connectors. The HMI display makes EB 60 WT operation convenient for users, who can also view fault messages and causes on the display.

The alerts are made possible by chiller’s ability to exchange control signals with the edge banding machine through the Harting connectors. The HMI display makes EB 60 WT operation convenient for users, who can also view fault messages and causes on the display.

“A decisive factor for us was that the EB 60 is very easy to maintain. For example, the filter mats only have to be cleaned every two to three weeks, despite the high dust level. The unit was installed six months ago, and we haven’t had to replace the filter mats yet. Thanks to the various alerts, we can perform preventive maintenance to increase our machine availability”

Modular and energy-efficient chiller technology

In a closed-circuit system, switchgear cabinets or electronic components are cooled by pumping cold water at a defined supply temperature through the switchgear cabinets in a pipe system.

After passing through the switchgear cabinets, the water flows back to the chiller at a higher temperature (return temperature). The chiller removes the temperature difference by cooling the water from the return temperature back to the supply temperature.

Pfannenberg offers chiller solutions covering the capacity from 1 to 70 kW, using water or oil as the refrigerant. Particularly in combination with air/water heat exchangers, water chillers (WT) provide an ideal system solution because all cooling task in a plant or machine can be implemented easily and economically using a closed-circuit pipe system.

The modular design of the EB series gives users a choice of up to 30 standard options, including UL certification. Good access from all sides enables easy and efficient maintenance. All components are rugged and top quality. In addition, Pfannenberg’s chiller is an especially energy-efficient chiller with load-based speed control that can reduce energy consumption by about 40% compared to the standard series.

“The Pfannenberg unit is top quality. You just switch it on and it works. It was delivered quickly, and the sales team put a lot of effort into it. The entire process was very smooth”

Pfannenberg is a global manufacturer of products and solutions developed to keep critical plant operations online and personnel safe.

Click here to get more information about Pfannenberg’s range of Chillers!

Protecting Man, Machine and the Environment… since 1954.

Topics: Packaged Chillers, Chillers