Select a filter fan appropriate for the electrical equipment in use, cooling demands, and environmental conditions

By Chris Marlow, Solutions Engineer

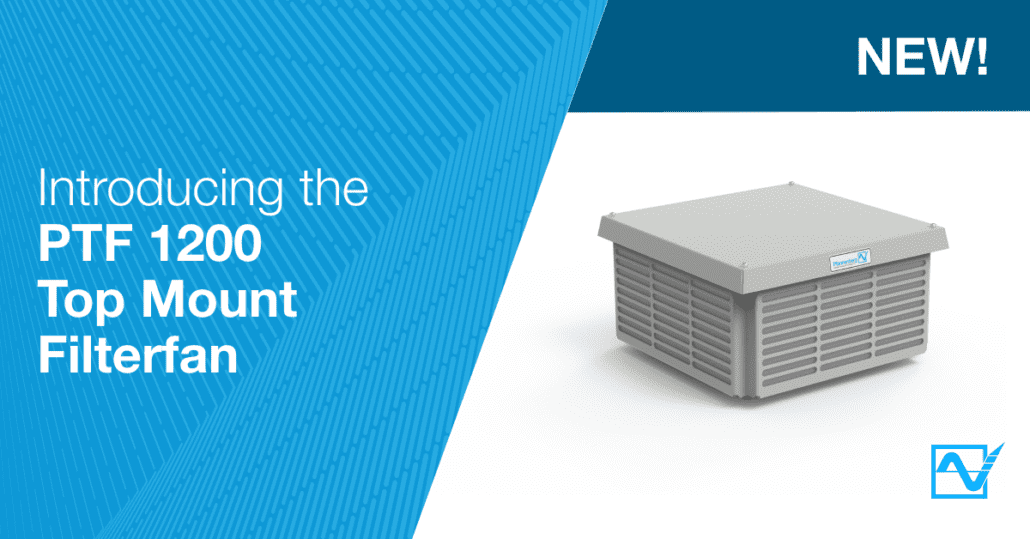

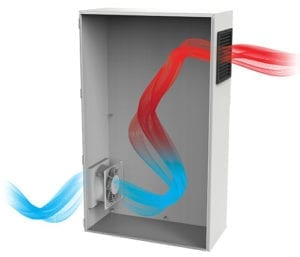

Filter fans perform a critical task of moving the hot air from within electrical enclosures to the external environment while also protecting equipment from ingress of harmful dust, water, or other materials. Cooling is necessary to protect sensitive electrical components from overheating and becoming damaged. When appropriate, filter fans are a popular choice for this cooling task due to their low energy usage and ease of installation.

The fan component of a filter fan provides this critical thermal protection, while filters keep airborne particles like dust from getting into the enclosures and damaging the equipment inside. Filter fans also help to protect equipment from water, ice, snow, animal ingress, or vandalism, depending on the environment.

Selecting the correct filter fan for a given application requires consideration of that application’s heat load information and what temperatures need to be maintained, as well as the environmental conditions.

Which Filterfan for which application?

Invented in 1958 by Otto Pfannenberg, the original Filterfan® has evolved over the last 50 years to provide protection for electrical enclosures in a variety of applications, specifically, in indoor, outdoor, or extreme environments. Each environment has particular considerations, and so filter fan design is custom-made to match those concerns.

Indoor Use

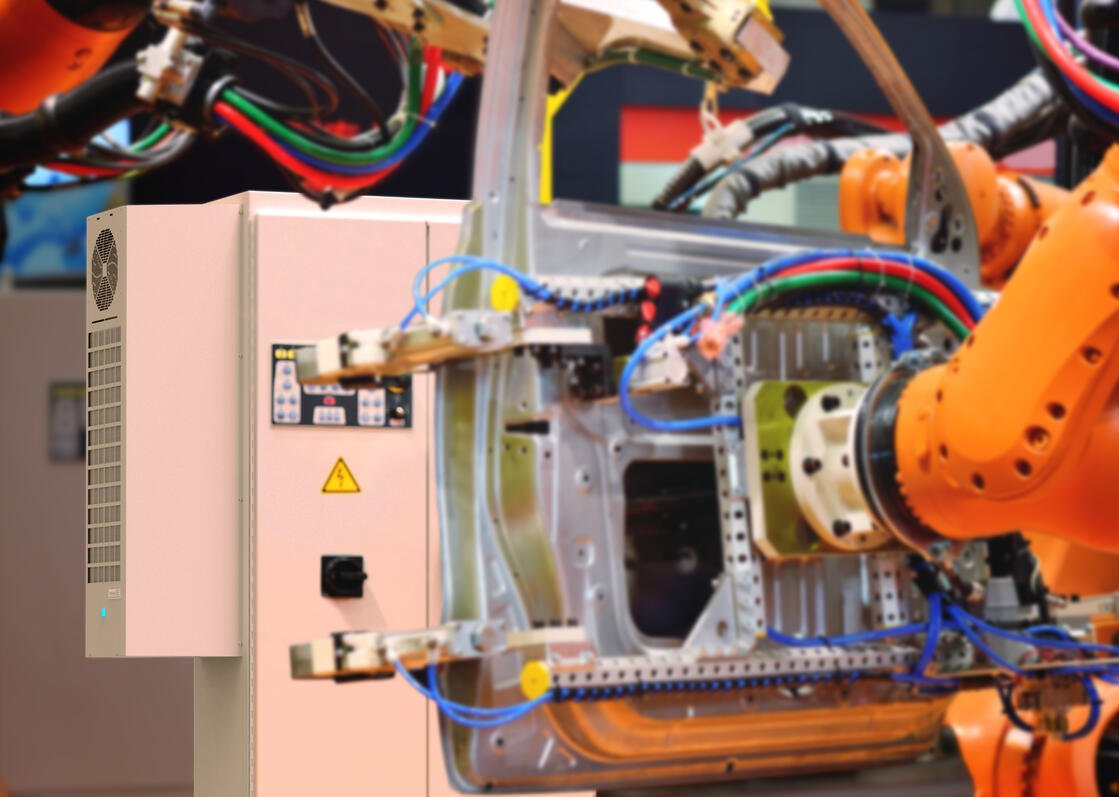

In indoor environments, filter fans can be used in applications such as test stands in manufacturing facilities, IT racks in data storage applications, or drive enclosures. Indoor filter fans are designed to protect these electrical enclosures using a fan, a filter, and louvers. This design provides needed cooling, protection against airborne particulates, and enables light washdown procedures. Pfannenberg, the company founded by the original Filterfan® inventor of the same name, remains the industry leader in filter fan design. Its indoor Filterfans 4.0 TM feature louvers with wing qualities and a lip at the end help pre-collect dust. Pfannenberg has also created a pleated filter design that provides more surface area with the same filter volume used compared to mesh filters, which allows for more dust to be collected before airflow is constricted.

In indoor environments, filter fans can be used in applications such as test stands in manufacturing facilities, IT racks in data storage applications, or drive enclosures. Indoor filter fans are designed to protect these electrical enclosures using a fan, a filter, and louvers. This design provides needed cooling, protection against airborne particulates, and enables light washdown procedures. Pfannenberg, the company founded by the original Filterfan® inventor of the same name, remains the industry leader in filter fan design. Its indoor Filterfans 4.0 TM feature louvers with wing qualities and a lip at the end help pre-collect dust. Pfannenberg has also created a pleated filter design that provides more surface area with the same filter volume used compared to mesh filters, which allows for more dust to be collected before airflow is constricted.

Outdoor Use

Outdoor filter fans have all of the same design considerations of indoor filter fans, with a focus on cooling and dust collection, but with the added considerations of weather, solar radiation, and animal ingress. Key applications for outdoor filter fans include battery storage, such as for solar panels, and pump stations with enclosed pumps. In these and other outdoor filter fan applications, enclosures protect electrical equipment from weather, animals, and other possible damage, but introduce cooling requirements in order to keep equipment close to ambient temperatures. Outdoor filter fans must therefore be designed like indoor ones, but with added protection against outdoor hazards. Pfannenberg’s 3R Filterfans® for outdoor use protect against heavy rain with water pathways and drain holes that are designed to draw water away from the fan instead of accumulating and causing flooding. This design, along with added seals, also protects against hazardous ice formation. Finally, the outdoor-specific 3R Filterfans® are designed with UV-resistant materials to avoid the degradation than can happen to unprotected plastics in the sun.

Outdoor filter fans have all of the same design considerations of indoor filter fans, with a focus on cooling and dust collection, but with the added considerations of weather, solar radiation, and animal ingress. Key applications for outdoor filter fans include battery storage, such as for solar panels, and pump stations with enclosed pumps. In these and other outdoor filter fan applications, enclosures protect electrical equipment from weather, animals, and other possible damage, but introduce cooling requirements in order to keep equipment close to ambient temperatures. Outdoor filter fans must therefore be designed like indoor ones, but with added protection against outdoor hazards. Pfannenberg’s 3R Filterfans® for outdoor use protect against heavy rain with water pathways and drain holes that are designed to draw water away from the fan instead of accumulating and causing flooding. This design, along with added seals, also protects against hazardous ice formation. Finally, the outdoor-specific 3R Filterfans® are designed with UV-resistant materials to avoid the degradation than can happen to unprotected plastics in the sun.

Extreme Environments

Though the outdoor filter fan design can cope with significant weather-related hazards, some environments, both indoors and outdoors, are simply too extreme for the above filter fan designs. These cases include industrial food processing or bakery applications where high pressure washdowns are necessary. It also includes outdoor applications in regions with significant snow accumulation that could block airflow, and enclosures that might be subject to vandalism, among others. In these cases, the addition of a rainhood provides the additional protection necessary to ensure uninterrupted filter fan and electrical component operation. The rainhood’s metal shell provides solid protection against breaking, hides the filter fan from vandalism, provides another barrier against the entrance of water in washdown procedures, and prevents snow from accumulating in the path of airflow. Pfannenberg’s Filterfan® + Rainhood combination is the market-leading solution for use in extreme environments.

Though the outdoor filter fan design can cope with significant weather-related hazards, some environments, both indoors and outdoors, are simply too extreme for the above filter fan designs. These cases include industrial food processing or bakery applications where high pressure washdowns are necessary. It also includes outdoor applications in regions with significant snow accumulation that could block airflow, and enclosures that might be subject to vandalism, among others. In these cases, the addition of a rainhood provides the additional protection necessary to ensure uninterrupted filter fan and electrical component operation. The rainhood’s metal shell provides solid protection against breaking, hides the filter fan from vandalism, provides another barrier against the entrance of water in washdown procedures, and prevents snow from accumulating in the path of airflow. Pfannenberg’s Filterfan® + Rainhood combination is the market-leading solution for use in extreme environments.

Tips for selecting the correct filter fan

Given all of the environmental and application considerations, there are a number of tips to keep in mind when selecting a filter fan for any given environment.

Determine if a filter fan is a viable option

The first step should always be to determine whether a filter fan is the correct cooling and protection solution for a given application. Answering “yes” to all three of the following questions means that a filter fan is likely a good cooling solution:

- Is the ambient temperature lower than the desired temperature within the enclosure?

- Is the environment free of corrosive airborne particulates and gases?

- Is the heat load within the range for which a filter fan can provide adequate cooling?

This third question, of course, leads into the next tip, since it might not be possible to determine whether the heat load is suitable for a filter fan right away.

Assess application needs

The next critical step is to collect as much information as is possible about the application, the enclosure size, the components inside enclosure, the temperature these components should be maintained at, any environmental hazards (sun, rain, snow, animals, etc.), and what the environment’s temperature range is. Additionally, other considerations like clearance requirements, washdown procedures, foot traffic around the filter fan, or other similar considerations should be noted. These considerations will help to determine not only the appropriate size, flow rate, and type of filter fan to use, but also helps to determine whether a metal rainhood is required and how the filter fan(s) should be configured.

Consult an expert

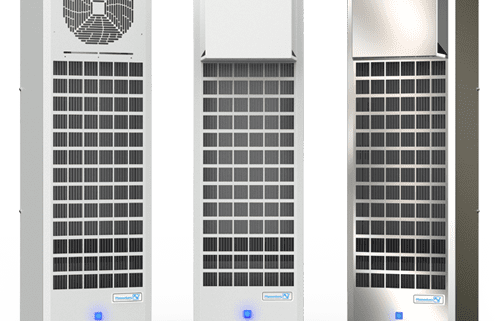

It is critically important to gather the information described in the last tip because cooling experts need that information to be able to specify the correct filter fan for each application. More information translates into better overall suitability for the application, and therefore the greatest assurance of balancing protection and cooling with cost efficiency and minimal maintenance. At Pfannenberg, experts analyze this information using specialized software to determine the appropriate size, flow rate, configuration, and environmental protections for the application’s ideal filter fan. Pfannenberg manufactures Filterfans® in seven different flow rates and several different sizes, and can configure these with a single exhaust, two exhausts, or with a fan in and fan out, depending on the application’s specific demands.

Consulting with experts not only ensures a right-sized solution that will ideally balance airflow, protection from the environment, and cost; doing so also helps to ensure that the filter fan will keep electrical components free from water and dust, and properly cooled, in order to extend the lifespan of those components. If a filter fan is too small, the components could overheat, leading to early failures, unplanned downtime, and additional cost. If a filter fan rated for indoor use is used outside, ice buildup or sun exposure could lead to broken seals and dangerous water incursion into the electrical enclosure.

When configured properly, the only maintenance required for filter fans is regular filter replacement to ensure that a consistent flowrate and cooling capacity can be maintained. The lifespan of a filter depends on the application –a bakery with fine dust requires more frequent filter changes than most manufacturing test stand applications – so experts should be consulted to determine the ideal maintenance schedule for each application.

Conclusion

Filter fans are critical to protecting electrical equipment from overheating, water, and airborne debris so that the equipment can continue to run safely and efficiently. Finding a filter fan suitable to each particular application and environment requires careful research and the assistance of experts. By considering heat load, environmental conditions, and other factors in consultation with an expert, it is possible to reduce maintenance needs and cost while keeping electrical equipment protected. In applications in indoor, outdoor, and extreme environments, well-designed filter fans keep electrical equipment functional and safe.

In indoor environments, filter fans can be used in applications such as test stands in manufacturing facilities, IT racks in data storage applications, or drive enclosures. Indoor filter fans are designed to protect these electrical enclosures using a fan, a filter, and louvers. This design provides needed cooling, protection against airborne particulates, and enables light washdown procedures. Pfannenberg, the company founded by the original Filterfan® inventor of the same name, remains the industry leader in filter fan design. Its indoor

In indoor environments, filter fans can be used in applications such as test stands in manufacturing facilities, IT racks in data storage applications, or drive enclosures. Indoor filter fans are designed to protect these electrical enclosures using a fan, a filter, and louvers. This design provides needed cooling, protection against airborne particulates, and enables light washdown procedures. Pfannenberg, the company founded by the original Filterfan® inventor of the same name, remains the industry leader in filter fan design. Its indoor  Outdoor filter fans have all of the same design considerations of indoor filter fans, with a focus on cooling and dust collection, but with the added considerations of weather, solar radiation, and animal ingress. Key applications for outdoor filter fans include battery storage, such as for solar panels, and pump stations with enclosed pumps. In these and other outdoor filter fan applications, enclosures protect electrical equipment from weather, animals, and other possible damage, but introduce cooling requirements in order to keep equipment close to ambient temperatures. Outdoor filter fans must therefore be designed like indoor ones, but with added protection against outdoor hazards.

Outdoor filter fans have all of the same design considerations of indoor filter fans, with a focus on cooling and dust collection, but with the added considerations of weather, solar radiation, and animal ingress. Key applications for outdoor filter fans include battery storage, such as for solar panels, and pump stations with enclosed pumps. In these and other outdoor filter fan applications, enclosures protect electrical equipment from weather, animals, and other possible damage, but introduce cooling requirements in order to keep equipment close to ambient temperatures. Outdoor filter fans must therefore be designed like indoor ones, but with added protection against outdoor hazards.  Though the outdoor filter fan design can cope with significant weather-related hazards, some environments, both indoors and outdoors, are simply too extreme for the above filter fan designs. These cases include industrial food processing or bakery applications where high pressure washdowns are necessary. It also includes outdoor applications in regions with significant snow accumulation that could block airflow, and enclosures that might be subject to vandalism, among others. In these cases, the addition of a rainhood provides the additional protection necessary to ensure uninterrupted filter fan and electrical component operation. The rainhood’s metal shell provides solid protection against breaking, hides the filter fan from vandalism, provides another barrier against the entrance of water in washdown procedures, and prevents snow from accumulating in the path of airflow.

Though the outdoor filter fan design can cope with significant weather-related hazards, some environments, both indoors and outdoors, are simply too extreme for the above filter fan designs. These cases include industrial food processing or bakery applications where high pressure washdowns are necessary. It also includes outdoor applications in regions with significant snow accumulation that could block airflow, and enclosures that might be subject to vandalism, among others. In these cases, the addition of a rainhood provides the additional protection necessary to ensure uninterrupted filter fan and electrical component operation. The rainhood’s metal shell provides solid protection against breaking, hides the filter fan from vandalism, provides another barrier against the entrance of water in washdown procedures, and prevents snow from accumulating in the path of airflow.