Pfannenberg Announces Partnership with GMN USA

Liquid Cooling solutions to be sold alongside spindle motors for streamlined experience

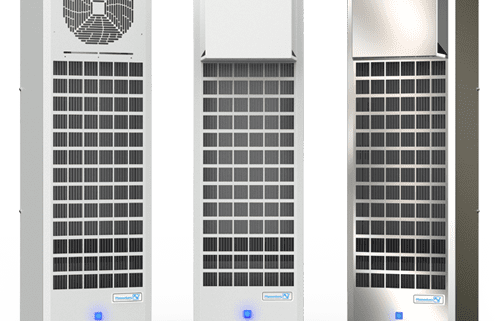

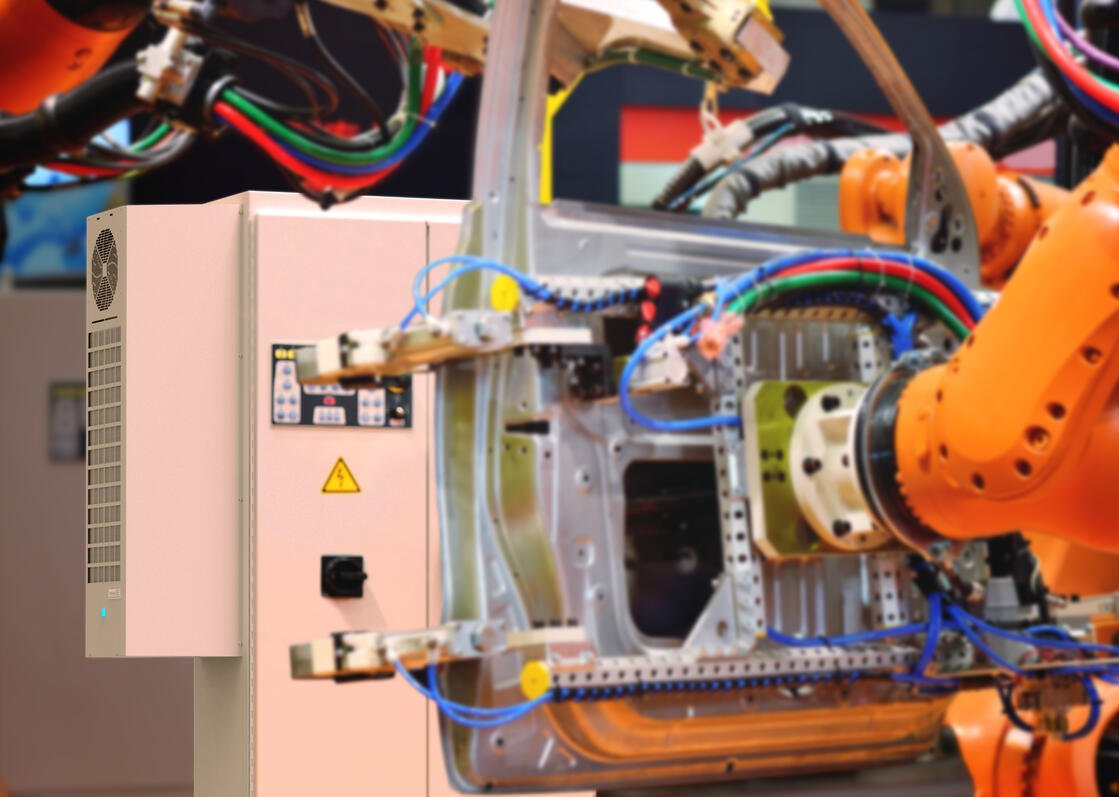

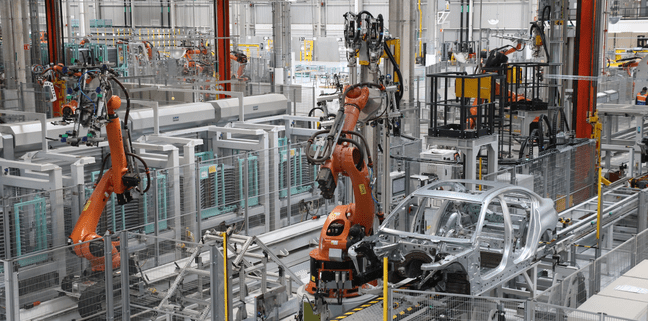

We are excited to announce a partnership with GMN USA, a supplier of machine tool spindles, drives, lubricators, and cord sets. This collaboration will supply GMN USA with Pfannenberg’s chillers, a liquid cooling solution that will be sold as a companion product alongside GMN’s spindle motors.

“I am excited to partner with GMN. Our teams working together will bring new growth to both organizations,” commented Barb Ross, Director of Channel and Representatives at Pfannenberg.

“It is an ideal combination of GMN’s high speed spindle technology with Pfannenberg coolant chillers,” says James Wong, Director for Global NEMA Product Management at Pfannenberg. “Our chillers will regulate and maintain the temperature of the spindles to increase reliability and reduce downtime for the end user.”

“GMN prides itself on partnering with high quality suppliers. We are looking forward to a great partnership with Pfannenberg. And look forward to growing together in the US.” Commented Glenn R Ledoux Vice President of Sales, GMN USA.

This alliance aims to better serve the machine tool industry in the US by featuring complementary products in one place. GMN USA offers a wide range of spindle support equipment in addition to Pfannenberg’s coolant chillers including oil/air lubricators, spindle drives, assemblies, and other accessories. GMN engineers provide support for both new and retrofit spindle applications based on individual customer needs.

Learn more about Pfannenberg’s liquid cooling solutions.

Learn more about GMN USA’s solutions.

The Press Release is available here.