Closed Loop Cooling for Electrical Enclosures in Commercial Bakeries

Solutions to Reduce Maintenance & Repair Costs

Electrical Enclosures and Enclosure Air Conditioners

Electrical enclosures and enclosure air conditioners often fall victim to flour damage in the make-up area of commercial bakeries. The “make-up area” is where dough is prepared by combining flour, moisture, and heat. When flour becomes wet due to ambient humidity levels, it forms a paste-like consistency. The build-up of flour and paste within the air conditioner leads to reduced performance and failure. Without proper cooling, the added stress and risk of failure for variable frequency drives and enclosure electronics can lead to costly repairs and downtime.

enclosure electronics can lead to costly repairs and downtime.

Many commercial bakeries still use air conditioners to cool electronics in the make-up area because they provide convenient closed-loop electronics cooling. But this solution is not sustainable due to high concentrations of particulates in the air, which eventually clog air conditioners such that they fail. However, opening the doors to the enclosure to provide needed cooling ultimately does more damage by compromising the NEMA 4/4X environment.

Electronics must receive proper cooling solutions. This is because they have a narrow “sweet spot” for cooling between 85 degrees and 95 degrees Fahrenheit. Lower temperatures risk condensation which can lead to water forming on electronics, while higher temperatures can cause heat stress failure.

A Solution for Commercial Bakeries – Liquid Cooling

Instead of air conditioning, a superior solution for bakeries is liquid cooling, which eradicates heat from enclosures in an efficient and cost-effective capacity. Liquid cooling proves especially well adapted to hot, dirty environments where it removes heat from machines. This makes liquid cooling the ideal solution for the makeup area in commercial bakeries.

When one of the fastest growing independent, family-owned baking manufacturers in the U.S. sought to optimize their resources, they turned to Pfannenberg. Drawing upon its decades of experience and expertise, Pfannenberg suggested a liquid cooling solution.

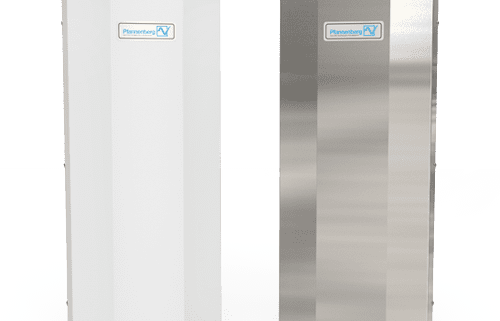

Pfannenberg’s PWS Series Air-to-Water Heat Exchangers now provides this leading bakery with a trouble-free cooling solution for their electrical enclosures in the make-up area. This solution easily operates in dusty environments where moisture and flour fill the air. To cool the bakery’s electrical units, the solution also utilizes glycol or a cool water source that the factory already has available.

In addition to sustainable cooling, the bakery improved the cleanliness of their electrical cabinets with this product. This is because PWS Series Air-to-Water Heat Exchangers have no filters, which means no down time results from changing filters or having them become clogged. The products also improved the efficiency of the cooled air by providing a stable temperature that sustained cool air, unlike previous AC units that would get clogged with airborne particles.

PWS Series Air-to-Water Heat Exchangers

By implementing four PWS Series Air-to-Water Heat Exchangers in the make-up area, the bakery overcame problems plaguing their enclosed electronics and achieved energy savings by eliminating the need for compressors and tapping into existing water or glycol lines that run throughout the manufacturing facility. The bakery also reduced maintenance costs by removing the risks of clogging and preventing unwanted repairs.

By partnering with Pfannenberg, this bakery took its business to the next level, and now seeks to implement even more Pfannenberg products to augment its manufacturing process. With products and solutions designed to meet high quality requirements and operate in the harshest conditions, Pfannenberg continues to prove itself a leader in innovative industrial solutions.

The two most important characteristics of creating a great tasting pie are the filling and the crust. For the filling, fruit is mixed with sugar, cinnamon, honey and other spices (depending on the type of filling) in a large sauce pan. Ingredients are heated and mixed to combine the flavors for the filling.

The two most important characteristics of creating a great tasting pie are the filling and the crust. For the filling, fruit is mixed with sugar, cinnamon, honey and other spices (depending on the type of filling) in a large sauce pan. Ingredients are heated and mixed to combine the flavors for the filling.