Pfannenberg Signaling Solutions comply to the European standard EN54-3

Providing effective fire alarms has gained prominence in recent years. A major reason of this concern is the increase of ambient noise also called “acoustic smog”. The use of headsets, hearing protection and the consideration of deafness made the requirement of visual and acoustic alerts essential to save lives when a dangerous situation occurs.

European standard EN54-3

In order to meet these needs, The European Standard EN54-23 is effective since January 2014 and now sets requirements, testing procedures and performance features for audible alarms. The general requirements and specifications are made regarding the range of the audible alarm thus giving a certified area. Every certified tone has to be measured independently due to varying sound pressure levels.

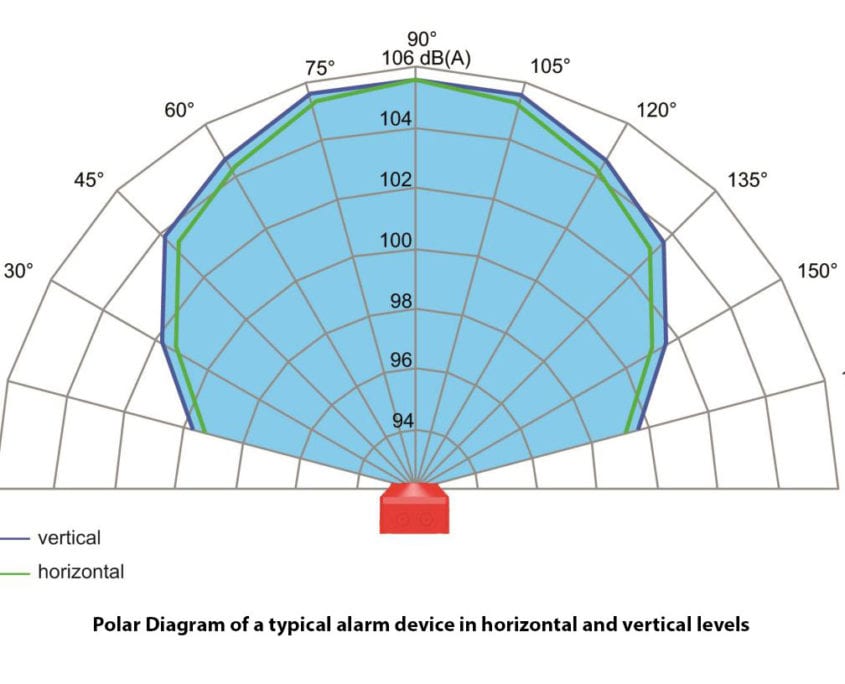

In particular, the horizontal and vertical angle radiation characteristics of the signaling devices must be checked and defined for each individual tone allowing the total volume of area to be correctly alerted. This is an essential part of the approval which must be considered during the planning phase, as the number and location of devices is critical to meet approval.

Planning of audible signaling devices

Planning an audible alarm must be a complete process and further technical characteristics must now be considered:

- The sound-pressure level [SPL] and the loudness (dB) of an audible alarm device is not identical for every tone. For planning requirements the SPL of the tone to be used on site always has to be taken as the basis for the plan. Never the loudest one available from the device.

- The audible alarm device achieves varying dB depending on the radiation angle from the device. The maximum dB is at a 90° angle (head on) in most cases. The level is significantly reduced at the sides (0° / 180°) (see fig. 1: Polar diagram)

Specifically in the planning phase the respective signaling range of industrial sounders must be determined. This results from the existing ambient sound level, or background noise, at the project site in connection with the radiation characteristics. The technology used to create the sound also has to be checked and taken into account.

Pfannenberg visual and audible signaling devices

Pfannenberg PYRA and PATROL series of industrial flashing sounders are the perfect option to comply with the highest European standards. Our experts assist our European customers to plan and design their signaling ranges with viable certified data and take into account their specific project conditions to determine and install the exact number of audible alarm devices required.

Click here to learn more about our Signaling Solutions!

To avoid operations grinding to a halt, specifically those with flour and high particulate in the air, Pfannenberg’s PWS Series Air to Water Heat Exchangers are an ideal solution for efficient, trouble free cooling for electrical enclosures.. Use an existing glycol or cool water source already available in the factory to cool your electrical cabinets.

To avoid operations grinding to a halt, specifically those with flour and high particulate in the air, Pfannenberg’s PWS Series Air to Water Heat Exchangers are an ideal solution for efficient, trouble free cooling for electrical enclosures.. Use an existing glycol or cool water source already available in the factory to cool your electrical cabinets.